Extended molecular dynamics: Seamless temporal coarse-graining and transition between deterministic and probabilistic paradigms

(M3TIAM) MULTISCALE-MULTIPHYSICS MODELLING OF TI ALLOY MEDICAL IMPLANTS BASED ON ADDITIVE MANUFACTURING TECHNOLOGY

Project details Funding: MSCA Postdoctoral Fellowships 2021. HORIZON-MSCA-2021-PF-01 Project coordinator: IMDEA Materials Project period: 01/02/2023 – 31/01/2025 IMDEA Materials' researchers Supervisor: Dr. Damien Tourret Fellow: Adrian Dante Boccardo Abstract Patient-customized bone

Phytic acid as a biomass flame retardant for polyrotaxane based phase change materials

Improved alignment and stress transfer in CNT fibre fabrics studied by in situ X-ray and Raman during wet-drawing

Symposium “Alloy and microstructure design of AHSS to improve their performance”.

7th International Conference of Engineering Against Failure (ICEAF) The DELIGHTED consortium members are organizing a Symposium ‘Alloy and microstructure design of AHSS to improve their performance’ within the frame of the 7th International Conference of Engineering Against

(OPE – IMDEA MATERIALS 2023 – 2024) EUROPEAN PROJECT OFFICE IMDEA MATERIALS INSTITUTE 2023 – 2024

Project details Funding: Preparación y gestión de proyectos europeos 2022 Project coordinator: IMDEA Materials. Project period: 01/01/2023 – 31/12/2024 IMDEA Materials' responsible Miguel Ángel Rodiel Abstract The Office of European Projects of Institute IMDEA Materials (OPE - IMDEA

(CARDIOBOOST-CM) BIOINGENIERÍA DE CÉLULAS SATÉLITE DE MÚSCULO ESQUELÉTICO COMO NUEVA ESTRATEGIA DE DIFERENCIACIÓN A CARDIOMIOCITOS Y REGENERACIÓN CARDIACA

Project details Funding: Biomedicina 2022 - Comunidad de Madrid Project coordinator: Centro Nacional de Investigaciones Cardiovasculares Carlos III (CNIC) Project period: 01/01/2023 – 31/12/2026 IMDEA Materials' researchers Dr. Jennifer Patterson Abstract Relevance. Heart failure is a

(NATURE) CONSOLIDATION AND STUDY OF BEHAVIOR UNDER HYDROGEN

Project details Funding: Strategic Projects Focused on the Ecological Transition and Digital Transition 2021. Ministry of Science and Innovation (MCIN/AEI); European Union "Next GenerationEU"/ PRTR.Project coordinator: Universidad Carlos III de MadridProject period: 01/12/2022 –

(DIGIBIOFAM) BIOBASED FLAME RETARDANT SYSTEM FOR SUSTAINABLE POLYMERS: MOLECULE DESIGN, DIGITAL SYNTHESIS, DIGITAL ANALYSIS, DATA-DRIVEN APPROACH

Project details Funding: Strategic Projects Focused on the Ecological Transition and Digital Transition 2021. Ministry of Science and Innovation (MCIN/AEI); European Union "Next GenerationEU"/ PRTR. Project coordinator: IMDEA Materials. Project period: 01/12/2022 – 30/10/2024 IMDEA Materials'

Nuevo detector sísmico barato y resistente – SINC

El Servicio de Información y Noticias Científicas (SINC) ha destacado el trabajo de IMDEA Materiales y la Universidad Politécnica de Madrid (UPM) en el desarrollo de un nuevo sensor de terremotos. Puedes leer el articulo, aquí:

(CATBYESE) HIGH-THROUGHPUT STRATEGIES FOR THE DISCOVERY OF NEW CATALYSTS FOR THE HYDROGEN ECONOMY THROUGH ELASTIC STRAIN ENGINEERING

Project details Funding: Strategic Projects Focused on the Ecological Transition and Digital Transition 2021. Ministry of Science and Innovation (MCIN/AEI); European Union "Next GenerationEU"/ PRTR. Project coordinator: IMDEA Materials. Project period: 01/12/2022 – 30/10/2024 IMDEA Materials'

Cuestionar el orden establecido: El nuevo grupo de investigación de IMDEA Materiales trata de ampliar los límites del conocimiento científico en el campo de los metamateriales.

Desde sus primeros días como investigador predoctoral, el Dr. Johan Christensen ha estado impulsado por el deseo de ampliar el conocimiento científico. El Dr. Christensen ha asumido recientemente un puesto en el Instituto IMDEA Materiales como investigador principal y líder del recién fundado

Seminario del Dr. Charles-André Gandin, del “CNRS & Mines Paris PSL – Francia” titulado: « Multiscale modeling of laser-powder bed fusion additive manufacturing». El día 17 de enero, a las 12:00, en el Auditorio.

Resumen: Most of Additive Manufacturing (AM) are solidification processes. As a result of the phase transformations, usual metallurgical features of arc welding processes are found, e.g., textured structures, intergranular hot tears, deviation from thermodynamic transformation paths, … The

Interface-charring catalysis enables fire-safe and mechanically reinforced epoxy via facile interfacial aggregation induction

On the Effect of Nucleation Undercooling on Phase Transformation Kinetics

Seminario del Dr. Valentin Vassilev, nueva incorporación de IMDEA Materiales, titulado: «In quest of accurate modelling of complex potential-energy surfaces: a Computational Chemistry and Machine Learning approach». El día 20 de enero, a las 12:00, en la Sala de Seminarios.

Resumen: Accurate modelling of chemical and physical interactions is crucial for obtaining thermodynamic and dynamical properties of any chemical system, enabling a myriad of possible applications. Many of these applications are computationally prohibitive when using advanced Computational

A phosphaphenanthrene-based derivative as multifunctional flame retardant for epoxy resins

DELIGHTED dissemination update

The DELIGHTED members continue to disseminate the outcomes of the project actively. The researchers from the University of Ghent and IMDEA Materials Institute participated in the 8th International Conference of the Hellenic Metallurgical Society (ICHMS8) in Patras, Greece, on

Seminario del Dr. Joaquín García Suárez, de la Escuela Politécnica Federal de Lausana (EPFL), titulado: «Data mesh refinement». El día 9 de enero, a las 12:00, en la Sala de Seminarios.

Abstract: Model-free data-driven computational mechanics (DDCM) is a new paradigm for simulations in solid mechanics. One of the its advantagesis the fact that it avoids regression-based, bias-prone constitutive modeling. However, many materials do display a simple linear response in the

The preparation of phosphorus and nitrogen-containing structure towards the enhancement of flame retardancy for thermoplastic polyurethane elastomer

Facile Fabrication of organic zirconium/inorganic phosphorus complex for super-efficiently flame-retardant epoxy resin

Potential energy-assisted coupling of phase change materials with triboelectric nanogenerator enabling a thermally triggered, smart, and self-powered IoT thermal and fire hazard sensor: Design, fabrication, and applications

Los materiales que convierten un coche de Fórmula 1 en la máquina más rápida y segura – The Conversation

The Conversation España ha publicado el tercer artículo de nuestra colaboración con The Conversation España. Puedes leer el artículo con nuestro director, José Manuel Torralba, sobre los materiales que hacen posible los coches actuales de Fórmula 1, aquí:

Tunable topological interface states in one-dimensional inerter-based locally resonant lattices with damping

Dr. Javier García

Javier LLorca

Líneas de InvestigaciónSus líneas de investigación se centran en el desarrollo de nuevos materiales para aplicaciones de ingeniería en los sectores del transporte, la energía y la salud. Las relaciones entre el procesado, la estructura y las propiedades de los materiales se establecen mediante

Simultaneously improving the fire safety and mechanical properties of epoxy resin with iron phosphonated grafted polyethylenimine

TEGylated Double-Walled Carbon Nanotubes as Platforms to Engineer Neuronal Networks

Defensa de doctorado de Thomas Isensee, titulada «Modelado multiescala de la cinética de crecimiento dendrítico con convección líquida» – 18 de enero de 2023.

La Defensa de Doctorado tendrá lugar a las 11:00 horas, en la sala verde de la Escuela de Ingenieros de Caminos, Canales y Puertos. La disertación se titula "Modelado multiescala de la cinética de crecimiento dendrítico con convección líquida". Fue asesorado por el Dr. Damien Tourret y el Prof.

Development of multifunctional highly-efficient bio-based fire-retardant poly(lactic acid) composites for simultaneously improving thermal, crystallization and fire safety properties

Structured sonic tube with carbon nanotube-like topological edge states

Tailored P/Si-decorated graphene oxide-based fire sensor for sensitive detection at low-temperature via local and remote wireless transmission

IMDEA Materiales representada entre los galardonados de este año por el IOM3

El Director de IMDEA Materiales, el Profesor José Manuel Torralba, ha recibido en Londres el premio anual Ivor Jenkins del Instituto de Materiales, Minerales y Minería (IOM3). Y el Profesor Torralba no fue el único galardonado con una conexión con IMDEA Materiales, ya que la Profesora Judith

Bright and Photostable Fluorescent Metal Nanocluster Supraparticles from Invert Emulsions

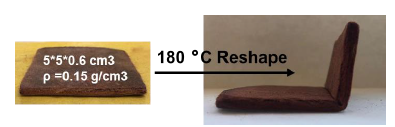

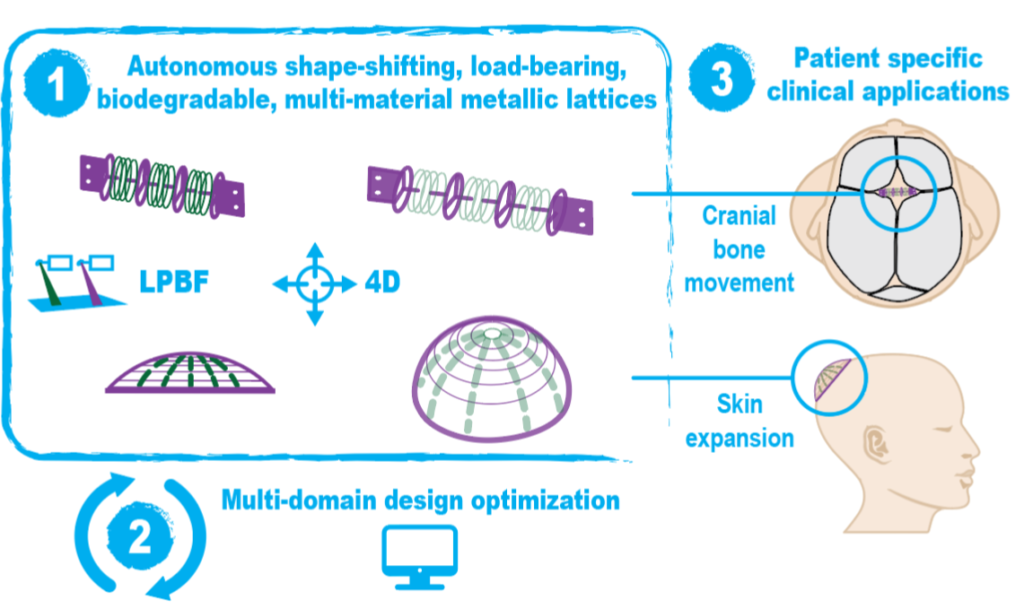

Reinventando la impresión médica 4D para implantes inteligentes de nueva generación

El Instituto IMDEA Materiales y la Universidad Politécnica de Madrid (UPM) celebraron recientemente el primer Taller Industrial y de Innovación Abierta, que marcó los primeros 18 meses del proyecto iMPLANTS-CM. El objetivo principal de iMPLANTS-CM, financiado por la Comunidad de Madrid, es el

Polyelectrolyte as highly efficient flame retardant to epoxy: Synthesis, characterization and mechanism

Understanding orientation-dependent plasticity in laser beam powder bed fusion stainless steel through crystal plasticity modelling

(DITTCE) IMPLANTABLE DEVICE FOR BRAIN TUMOR TREATMENT USING ELECTRICAL FIELDS

Project details Funding: Projects on Strategic Lines 2022. Project coordinator: Universidad Politécnica de Madrid Project period: 01/12/2022 – 30/11/2025 IMDEA Materials' researchers Dra. Mónica Echeverry Rendón Dr. Javier LLorca Martínez Abstract The main objective is to develop a fully

(MAT4BAT) NANOSTRUCTURE NETWORK ELECTRODES TO REALISE THE HIGH ENERGY DENSITY 3B/4A BATTERY

Project details Funding: Strategic Projects Focused on the Ecological Transition and Digital Transition 2021. Ministry of Science and Innovation (MCIN/AEI); European Union "Next GenerationEU"/ PRTR. Project coordinator: Fundación IMDEA Materiales Project period: 01/12/2022 – 30/11/2024 IMDEA

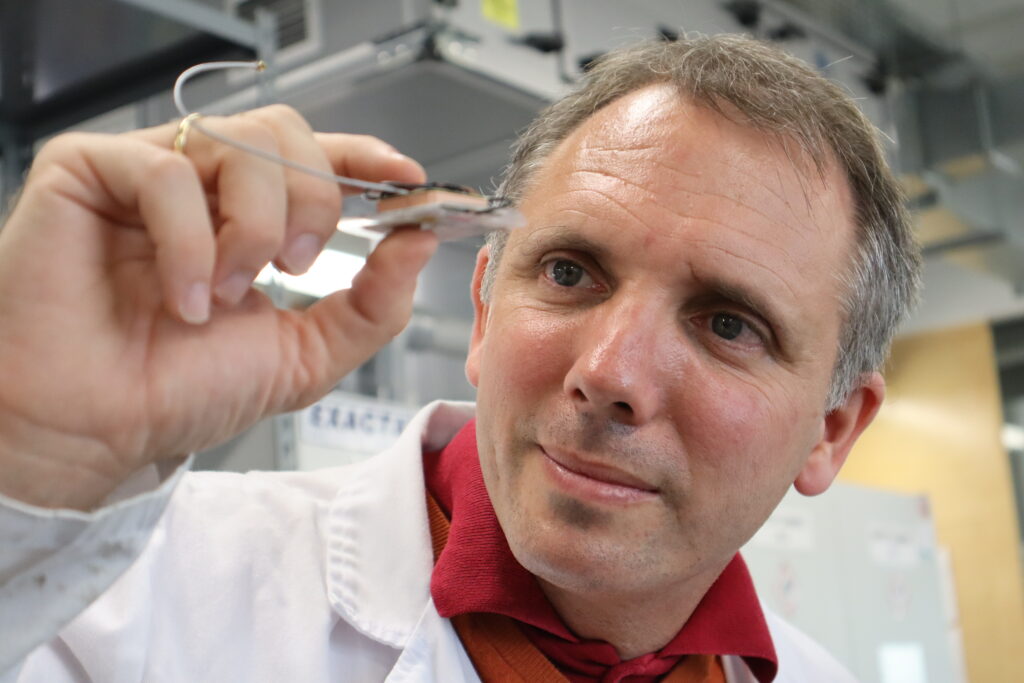

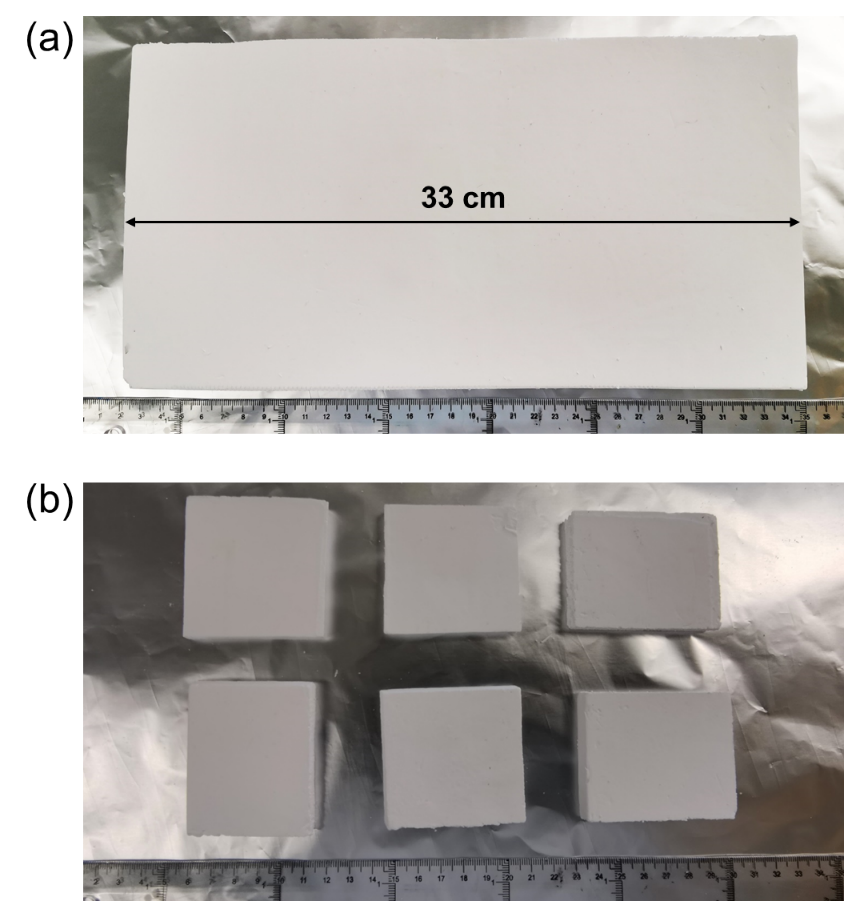

High-resolution TENGS for earthquakes ground motion detection

Defensa de doctorado de Mohammad Elahi, titulada «Modelado computacional de la fabricación de metales por fusión de lecho de polvo» – 2 de diciembre de 2022.

La Defensa de Doctorado tendrá lugar a las 11:00 horas, en el "aula C" de la Escuela Técnica Superior de Ingenieros Industriales. La disertación se titula "Modelado computacional de la fabricación de metales por fusión de lecho de polvo". Fue asesorado por el Prof. Ignacio Romero y el Dr. Damián

Influence of minor tensile stress on the oxidation behavior of powder metallurgy superalloy

La receta para conseguir granates a partir de cemento, y no es alquimia – The Conversation

Recientemente se ha publicado el segundo artículo de nuestra colaboración con The Conversation España. Puedes leer el artículo con nuestro director, José Manuel Torralba, sobre cómo convertir el cemento en granates,

Investigation of magnesium hydroxide functionalized by polydopamine/transition metal ions on flame retardancy of epoxy resin

Investigadores de IMDEA Materiales buscan materiales que alerten de un incendio antes de que se produzca – Cadena SER

El periodista David Callejo de la Cadena SER Madrid Sur habla con nuestro investigador, el Dr. Antonio Vázquez sobre el trabajo de IMDEA Materiales en desarrollar una nueva generación de sensores de incendio. Puedes escuchar la entrevista completa,

IMDEA Materiales celebra la Semana de la Ciencia

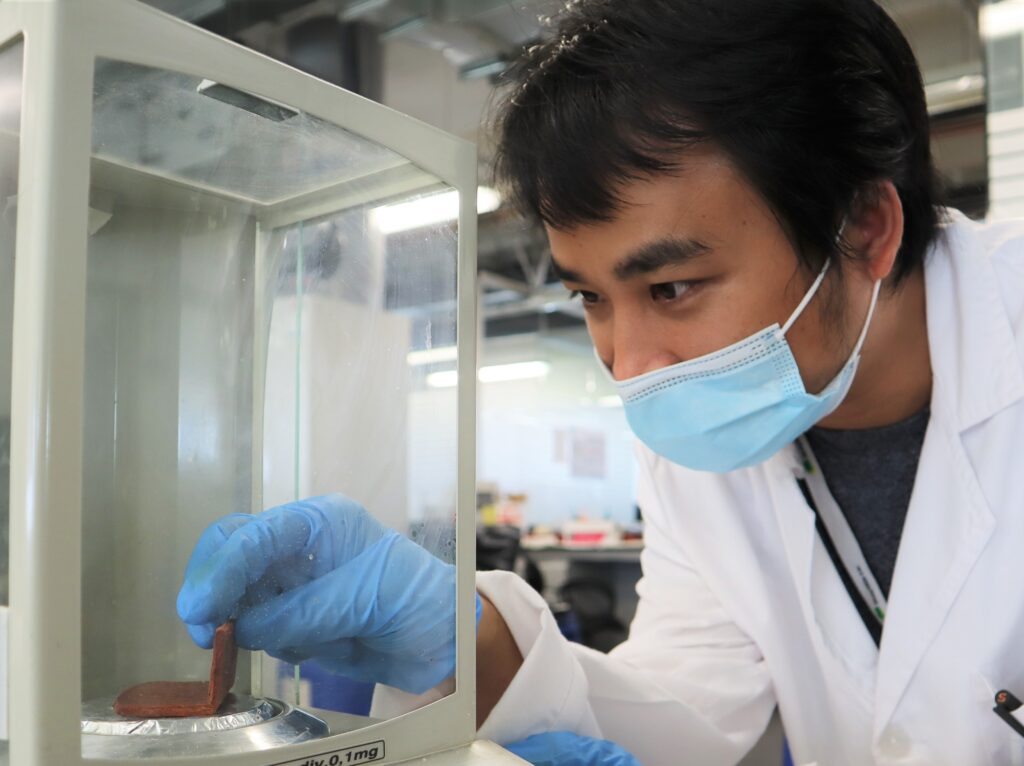

El Instituto IMDEA Materiales celebró la Semana de la Ciencia 2022 con una visita de los alumnos del Colegio Retamar de Madrid. Los proyectos BIOMET4D y BioImplant-ITN fueron dos de los focos de atención de las actividades. Los investigadores predoctorales Ángela Castro María del grupo de

Effect of cobalt on γ′ coarsening behavior of Ni-base powder metallurgy superalloy

«First Year Assessment» de Shuanglan Du, titulado «Marine-derived chitosan-based thermosensitive hydrogels and their applications in anti-aging»- 23 de noviembre, 2022 – 12:00 pm.

Resumen: El antienvejecimiento se ha convertido en un importante tema de investigación en el campo de las ciencias biológicas modernas. Es interesante considerar los hidrogeles para aplicaciones antienvejecimiento debido a su estructura única. En los últimos años, nuevos hidrogeles basados en

A facile technique to investigate the char strength and fire retardant performance towards intumescent epoxy nanocomposites containing different synergists

Seminario de la Dr. Sandra Camarero, del Instituto POLYMAT (Pais Vasco), titulado: «Form Follow Function vs Function Follows form: a shift in tissue regeneration». El día 2 de diciembre, a las 12:00, en la Sala de Seminarios.

Resumen:La Ingeniería de Tejidos surgió a principios de los años 90 sobre la base de la fabricación de andamios de biomateriales de diseño para guiar la unión, distribución, diferenciación y depósito de una matriz extracelular (ECM) característica del tejido objetivo. Las células son capaces de

First-principles analysis of the Al-rich corner of Al-Li-Cu phase diagram

First Year Assessment of Wen Ye, entitled“High-performance Flame-retardant Microspheres (FRMs) via Controllable Core-Shell Structure: Preparation, Characterization and Mechanisms» – November 11th, 2022 – 09:00 am (online)

Abstract:A novel series of FRMs was synthesized by suspension polymerization which had coreshell structure and complete spherical morphology. The core material is composed of a variety of flame-retardant components, some phosphate ester flame-retardant such as BDP, RDP, TPP etc. (or several of them)

IMDEA Materiales y la UPM exponen la fabricación aditiva y la biomedicina del futuro

El Prof. Andrés Díaz Lantada y el Dr. Jon Molina-Aldareguia, de la Universidad Politécnica de Madrid (UPM) y el Instituto IMDEA Materiales, han destacado los "avances significativos" conseguidos en la impresión 4D de materiales con cambio de forma y en dispositivos médicos gracias al proyecto

Aleaciones de alta entropía para materiales sorprendentes – RNE

La Radio Nacional de España (RNE) ha presentado una entrevista con el director de IMDEA Materiales, el Profesor José Manuel Torralba, sobre el potencial de las aleaciones de alta entropía en su popular podcast científico "A hombros de gigantes" con el periodista Manuel Seara Valero. Puede

Diseñan una nueva mascarilla inteligente llamada a revolucionar el mercado – ConSalud

El periodista Ángel Luis Jiménez de ConSalud.es ha hablado con el investigador visitante del IMDEA Materiales José Sánchez de Río Sáez sobre el diseño de una nueva "mascarilla inteligente" que puede seguir las constantes vitales del usuario. La máscara es uno de los resultados del proyecto

La novedosa mascarilla inteligente con una utilidad más allá de las pandemias

Investigadores del Instituto IMDEA Materiales, en colaboración con la Universidad Politécnica de Madrid y la Universidad Rey Juan Carlos, han desarrollado una nueva mascarilla inteligente capaz de monitorizar la respiración.La mascarilla tiene numerosas ventajas respecto a las mascarillas

Nuevos miembros del equipo – Octubre, 2022

Cada mes, damos la bienvenida a nuevos miembros del equipo de IMDEA Materiales. Aquí puede encontrar un breve perfil de nuestras incorporaciones más recientes. Burcu Ozdemir Me llamo Burcu Ozdemir y soy de Bursa, Turquía. Recientemente he terminado mi máster en Ciencia e Ingeniería de los

Smart Low-temperature responsive fire alarm based on MXene/Graphene oxide film with wireless transmission: Remote real-time luminosity detection

PLA aerogel based phase-change composites for thermal energy storage and heat management

Patent details Status European patent filedPCT extension Application number EP22383056.3PCT/EP2023/080316 Priority date 2 November 2022 Inventors De-Yi Wang, Guangzhong Yin Applicant IMDEA Materials Institute, Universidad Francisco

Seminario del Dr. Carlos Ruestes, postdoctoral de Marie Skłodowska-Curie en IMDEA Materials, titulado: “Deformation mechanisms in metals – Insights from molecular dynamics simulations”. El jueves 10 de noviembre, a las 12:00, en la Sala de Seminarios.

Resumen:La interpretación de experimentos que prueban las propiedades mecánicas de los materiales a menudo se ve limitada por la falta de herramientas adecuadas para una inspección operativa de los mecanismos de deformación. Las simulaciones de dinámica molecular ofrecen la posibilidad de realizar

Rational Amphiphilic Ligand Engineering Enables Enhanced Stability and Efficiency of CsPbBr3 Nanocrystals Based Light Emitting Diodes

El desarrollo de sensores para detectar incendios antes de que se inicien – Tech Xplore

Tech Xplore ha destacado la investigación en curso del Instituto IMDEA Materiales para desarrollar una nueva generación de sistemas de seguridad contra incendios. El artículo completo está disponible aquí: https://techxplore.com/news/2022-11-sensor-technology.html

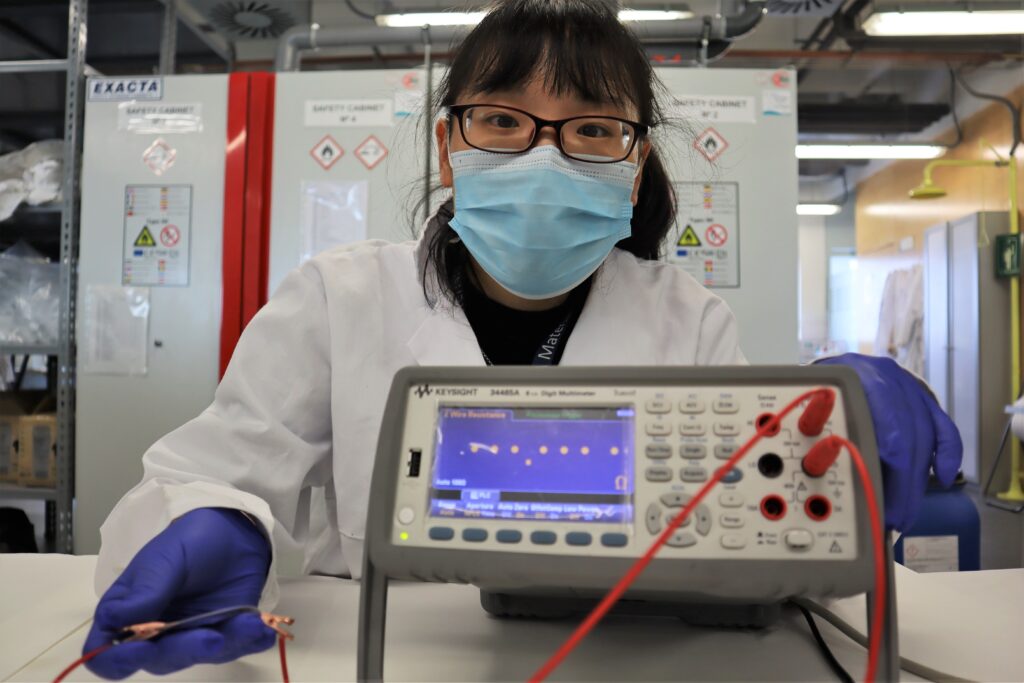

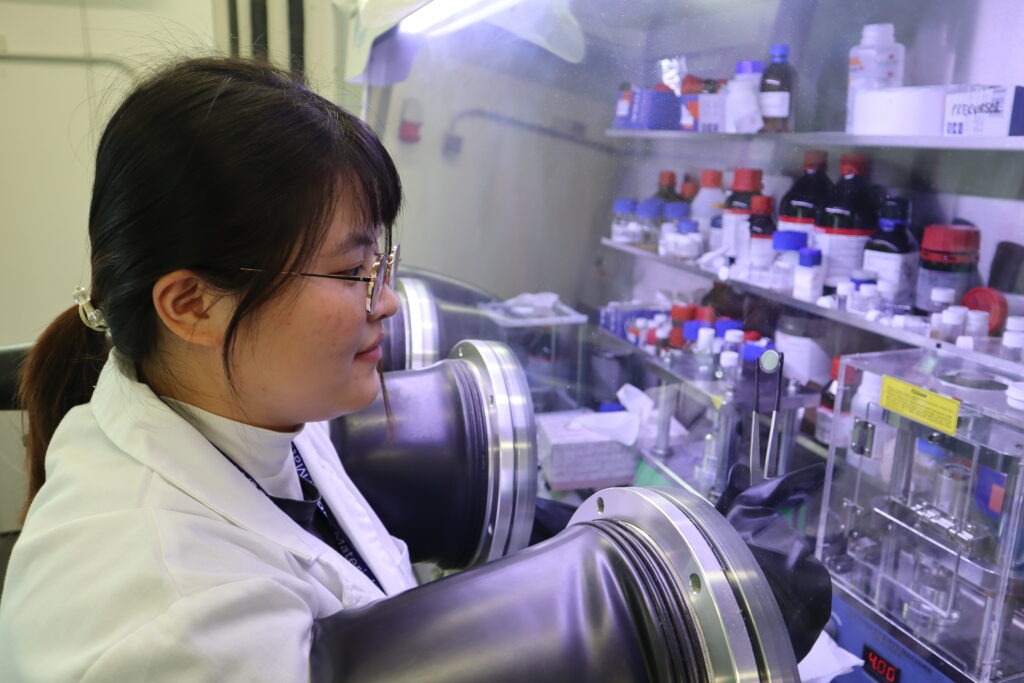

Science X presenta la investigación de IMDEA Materiales sobre electrolitos en estado sólido para baterías de ion de litio

Science X ha publicado el trabajo de la investigadora de IMDEA Materiales, Mingyang Zhang, para desarrollar un electrolito de estado sólido que mejore la seguridad de las baterías de ion de litio. Puedes consultar el artículo (contenido en inglés) completo aquí:

Paloma Hidalgo

Dr. Paloma Hidalgo Manrique joined IMDEA Materials in 2012 as a postdoctoral researcher after completing her PhD in high-strength aluminium alloys at the National Centre for Metallurgical Research. At IMDEA, Dr. Hidalgo was part of what is now known as the Sustainable Metallurgy research group under

Alumni en el Punto de Mira – La Dra. Paloma Hidalgo

Desde el comienzo de su carrera científica trabajando en aleaciones de magnesio más resistentes para la industria del transporte hasta su proyecto actual relacionado con los implantes de magnesio biodegradables, el trayecto profesional de la Dra. Paloma Hidalgo Manrique se ha centrado en sacar el

Los investigadores del Instituto IMDEA Materiales se sitúan entre los mejores científicos del mundo

10 científicos de IMDEA Materiales han sido incluidos en las listas anuales de la Universidad de Stanford del 2% de los mejores científicos del mundo. - Las clasificaciones, que incluyen listas separadas dedicadas a las actividades de investigación de los 12 meses anteriores y a los logros de

IMDEA Materiales desarrolla nuevos sensores para detectar incendios antes de que empiecen

Investigadores del Instituto IMDEA Materiales están trabajando en sistemas de seguridad contra incendios que puedan detectar y avisar del riesgo de incendio antes que éste se produzca. Las alarmas contra incendios suelen funcionar detectando la presencia de humo, llamas o niveles de monóxido de

Processing and mechanical properties of novel biodegradable poly-lactic acid/Zn 3D printed scaffolds for application in tissue regeneration

Multiscale simulation of powder-bed fusion processing of metallic alloys

Non-Hermitian elastodynamics in gyro-odd continuum media

Influence of Addition of Antibiotics on Chemical and Surface Properties of Sol-Gel Coatings

«First Year Assessment» de Mingyang Zhang , titulado «Fire safety enhanced electrolytes for lithium ion batteries: materials, methods, and mechanism»- 27 de octubre, 2022 – 12:00 pm.

Resumen: El desarrollo de electrolitos de estado sólido compuestos (CSSE) avanzados se considera una de las direcciones más prometedoras para lograr avances en la tecnología de baterías de litio. Para mejorar el rendimiento general de los electrolitos, como las propiedades mecánicas, el

High-Performance Room-Temperature Conductometric Gas Sensors: Materials and Strategies

Electrolitos de estado sólido, una solución a los problemas de seguridad de las baterías de ion de litio

Investigadores de IMDEA Materiales están trabajando en el desarrollo de un electrolito de estado sólido compuesto (CSSE) con propiedades ignífugas para baterías de ion de litio. El objetivo de la investigación es resolver uno de los principales problemas a los que se enfrenta la actual generación

Seminario del Prof. Jose A. Rodríguez-Martínez de la Universidad Carlos III de Madrid, titulado: «Localización plástica dinámica y fragmentación de metales impresos porosos: experimentos de impacto y modelado multiescala». El día 24 de octubre, a las 12:00, en la Sala de Seminarios.

Resumen: Comprender el daño, la localización y la fractura en sólidos dúctiles y estructuras sujetas a impactos de alta velocidad o cargas explosivas tiene importancia en la industria aeroespacial, aplicaciones militares, ingeniería civil y aplicaciones geofísicas. Los cráteres meteóricos, el

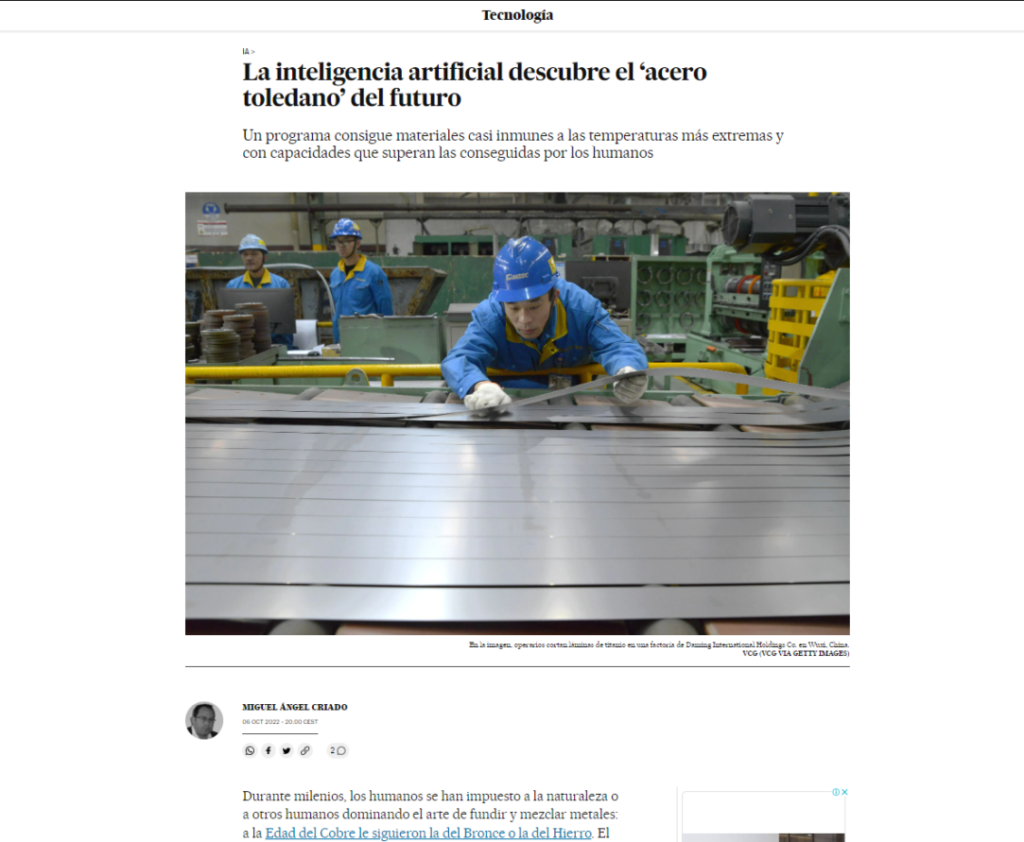

La inteligencia artificial descubre el ‘acero toledano’ del futuro – El País

Nuestro director, el Prof. José Manuel Torralba, ha hablado con Miguel Ángel Criado de El País sobre el papel que juega la inteligencia artificial en el descubrimiento de los materiales del futuro. Puedes leer el artículo completo

SaluDigital destaca el trabajo de IMDEA Materiales con implantes biodegradables a base de zinc

El periodista Ángel Luis Jiménez de SaluDigital (https://www.consalud.es/saludigital/) ha hablado con el investigador de IMDEA Materiales Guillermo Domínguez sobre su trabajo con una nueva generación de implantes biodegradables para su uso como stents cardiovasculares. Puedes ver el artículo

Burcu Ozdemir

A novel highly-efficient bio-based fire retardant for poly (lactic acid): Synthesis, preparation, property and mechanism

Endothelial function after the exposition of magnesium degradation products

Structured sonic tube with carbon nanotube-like topological edge states

Effect of C content on microstructure and mechanical properties of Cr-based hard composites obtained by different sintering methods

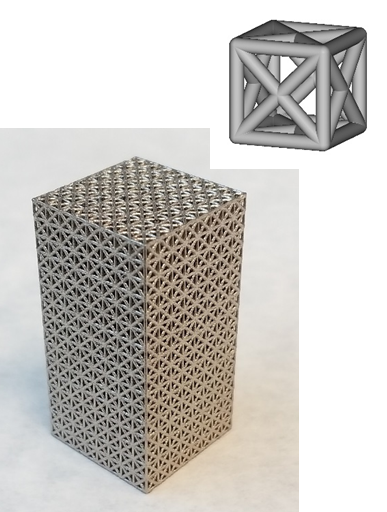

IMDEA Materiales avanza en el campo de los metales porosos ligeros para implantes óseos y tecnologías de transporte

El Instituto IMDEA Materiales está coordinando un nuevo proyecto internacional dedicado a estructuras metálicas porosas que combinan peso ligero con alta resistencia. La elevada relación superficie-volumen de los metales porosos, junto con sus propiedades mecánicas optimizables, los convierte en

La predicción de la plasticidad de los metales y sus beneficios para la industria

El investigador visitante Dr. Douglas Spearot espera que su colaboración con IMDEA Materiales dé lugar a técnicas de simulación mejoradas para predecir la plasticidad y la evolución de la microestructura en metales, lo que supondrá beneficios clave para las industrias aeronáutica y del

Diffusion coefficients and atomic mobilities in fcc Ag–Ge and Cu–Ge alloys: Experiment and modeling

«First Year Assessment» de Yuyao Liu , titulado «Development of biodegradable polymers for tissue engineering»- 14 de octubre, 2022 -12:00 hr.

Resumen: La ingeniería de tejidos y la medicina regenerativa se visualizan actualmente como excelentes alternativas para la rehabilitación o sustitución de tejidos dañados mediante el uso de andamios. Sin embargo, sigue siendo un desafío cómo seleccionar los materiales y sus métodos de

Data-Driven Experimental Design of Rheological Clay-Polymer Composites

Decimotercera Noche Europea de los Investigadores en Madrid

Investigadores de los 7 institutos de IMDEA hablarán de las cinco Misiones de la UE vistas por ellos (I) Nuestras compañeras Isabel Gómez y María Dolores Martín (Lola) serán las protagonistas de este gran encuentro. Los presentadores de este acto serán nuestro Director, Prof. José Manuel

Convective effects on columnar dendritic solidification – A multiscale dendritic needle network study

ML-based porosity inspection method for composite materials

Patent details Status Spanish patent granted Concession number ES2947809 A1 Inventors Federico Sket, Juan Ignacio Caballero, Carlos Daniel González , Ernestina Menasalvas Ruiz y Consuelo Gonzalo Martín Priority date 9 May

Smart mask that monitors breath rhythm

Patent details Status Spanish patent granted Concession number ES2935558 B2 Inventors De-Yi Wang, Xiang-Ao, José Sánchez del Río, David Patrizi, Alejandro Ureña, Antonio del Bosque, María Sánchez, Xoan Xosé Fernández Applicants IMDEA Materials Institute, Universidad Politécnica de Madrid,

Recyclable and bendable vitrimer core resins for shapeable sandwich structures

Patent details Status European patent filed Application number EP22382656.1 Priority date 11 July 2022 Inventors De-Yi Wang, Xuebao Lin Applicant IMDEA Materials Institute Transfer opportunity License of

Quien controle los materiales venideros dominará el mundo – 20minutos

El periódico online más leído de España, 20minutos.es, ha destacado al Instituto IMDEA Materiales y a nuestro Director, José Manuel Torralba, en un artículo sobre los materiales del futuro y las aleaciones de alta entropía. Puedes leer el artículo completo

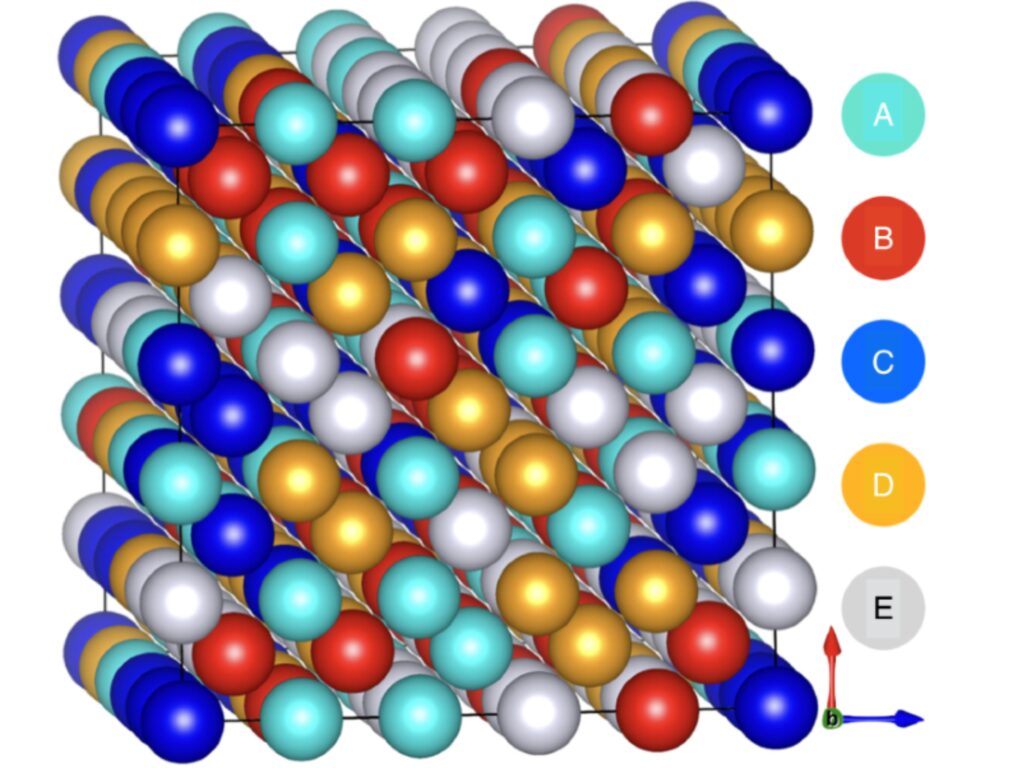

Tenemos la fórmula para crear supermateriales que rozan los principios de la magia: las aleaciones de alta entropía

José Manuel Torralba, IMDEA MATERIALES El Elinvar is a unicorn, a new material that once seemed impossible, created by humans using principles that border on magic: the principles that make high-entropy alloys possible. El Elinvar tiene una excepcional propiedad que tira por tierra cualquier libro

Cobalt ions loaded polydopamine nanospheres to construct ammonium polyphosphate for the improvement of flame retardancy of thermoplastic polyurethane elastomer

Bright and stable gold nanocluster assemblies by silica/zirconia double-shell encapsulation

(PORMETALOMICS) POROUS METAL GENOMICS FOR TAILORING MECHANICAL PROPERTIES OF LIGHT-WEIGHT 3D-PRINTED ARCHITECTURES

Project details Funding: International Collaboration Projects PCI2022-1. Ministry of Science and Innovation (MCIN/AEI); European Union "Next GenerationEU"/ PRTR. Project coordinator: IMDEA Materials. Project period: 01/09/2022 – 31/08/2025 IMDEA Materials' researchers Dr. Maciej

IMDEA Materiales trabaja en una nueva generación de materiales compuestos sostenibles con propiedades ignífugas. Un nuevo paso hacia la economía circular.

Los nuevos materiales compuestos reciclables de estructura sándwich podrían sustituir a los materiales pocos ecológicos que se utilizan ampliamente en una variedad de industrias. Los materiales que se están desarrollando actualmente también ofrecen un rendimiento y una capacidad de diseño

IMDEA Materiales investiga los materiales del futuro: OndaMadrid

La periodista Nieves Herrero ha entrevistado al investigador de IMDEA Materiales Guillermo Domínguez en el programa Madrid Directo de OndaMadrid. Puedes escuchar la entrevista completa aquí:

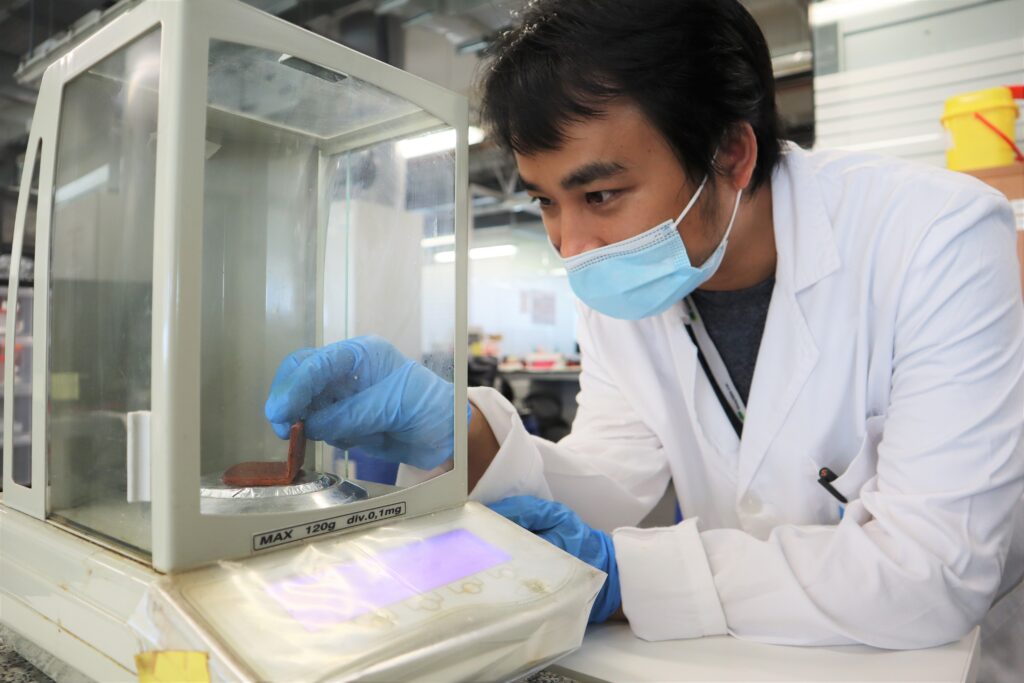

Actualidad Aeroespacial, CompositesWorld entre los que destacan el papel de IMDEA Materiales en DOMMINIO

El papel de IMDEA Materiales en el proyecto internacional Digital Method for Improved Manufacturing of Next-Generation Multifunctional Airframe Parts o DOMMINIO ha sido destacado en varios medios. Entre ellos, Actualidad Aeroespacial, CompositesWorld, La Vanguardia y La Razón. Puedes consultar el

(MENAWIR) Mechanics of Nanoporous W under irradiation

Project details Funding: MSCA Postdoctoral Fellowships 2021. HORIZON-MSCA-2021-PF-01 Project coordinator: IMDEA Materials Project period: 01/09/2022 – 31/08/2024 Website: IMDEA Materials' researchers Supervisor: Prof. Javier Segurado Fellow: Carlos Ruestes Abstract The MeNaWir project

Nabil Abomailek

Blanca Limones

IMDEA Materiales se suma al esfuerzo por construir un futuro más sostenible a través de la impresión 3D

El proyecto CONSTRUCTADD, recientemente lanzado y coordinado por el Politecnico di Milano, se centra en la aplicación de la impresión 3D de metales en el sector de la construcción de acero para reducir los residuos y las emisiones. El papel de IMDEA Materiales en el proyecto consistirá en el

Alumni en el Punto de Mira – El Dr. Pablo Romero

Desde el inicio de su carrera científica, el ex-investigador de IMDEA Materiales, el Dr. Pablo Romero, ha buscado el equilibrio perfecto entre sus dos pasiones de hacer investigación fundamental y aplicarla en el mundo real. Romero estuvo en el Instituto IMDEA Materiales de 2012 a 2016 mientras

Boosting the performance of soft carbon negative electrode for high power Na-ion batteries and Li-ion capacitors through a rational strategy of structural and morphological manipulation

Dr. Néstor Oscar Rossi Cabral

Alumni en el Punto de Mira – El Dr. Olben Falcó

Dado que el Instituto IMDEA Materiales solo abrió sus puertas en 2007, todavía no ha habido muchas oportunidades para que varias generaciones de la misma familia se incorporen sus filas. Sin embargo, una de las excepciones se encuentra en el caso del antiguo investigador postdoctoral, el Dr.

The effect of composition and microstructure on the creep behaviour of 14 Cr ODS steels consolidated by SPS

Seminario del Prof. Douglas E. Spearot, de la Universidad de Florida y actual visitante en IMDEA Materiales, titulado: “Simulating Plasticity in Metals at Atomistic and Mesoscopic Length Scales”. El jueves 22 de septiembre, a las 12:00, en la Sala de Seminarios.

Resumen:El desarrollo de modelos precisos y simulaciones de deformación plástica en materiales metálicos requiere una comprensión del comportamiento de los defectos y modos de deformación en metales en múltiples escalas de longitud y tiempo. En esta presentación, se resumirán los esfuerzos recientes

(SALMONE) SYNTHESIS AND ASSEMBLY OF LONG METAL OXIDE NANOWIRES FOR ENERGY

Project details Funding: Ministerio de Ciencia e Innovación - Plan Estatal de Investigación Científica y Técnica y de Innovación 2021-2023 - Subprograma Estatal de Generación de Conocimiento (Convocatoria cofinanciada con fondos FEDER). Project coordinator: IMDEA Materials Project period:

(UNIYARNS) UNIVERSAL PROCESSING ROUTE FOR HIGH-PERFORMANCE NANOSTRUCTURED YARNS

Project details Funding: ERC-2021-COG. European Research Council Executive Agency (ERCEA)Project coordinator: IMDEA Materials.Project period: 01/09/2022 – 31/08/2027 IMDEA Materials' researchers Dr. Juan José Vilatela Abstract Yarns are a natural architecture to

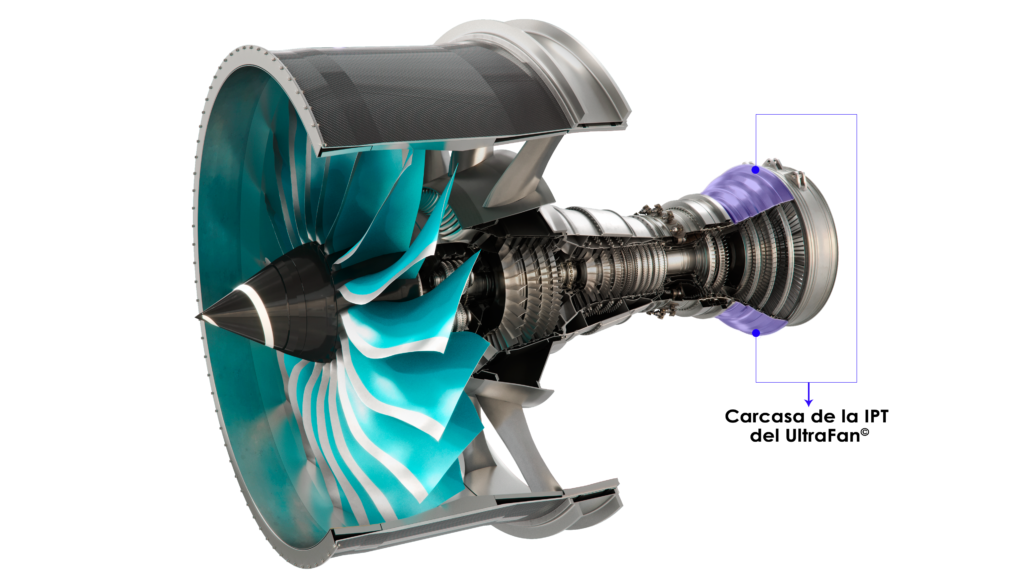

Cómo IMDEA Materiales ayudó a ITP Aero a desarrollar la turbina del UltraFan de Rolls-Royce, el mayor prototipo de motor aeronáutico turbofan del mundo

Como miembro del proyecto europeo HIPped Ultrafan IPT Casing (HUC), gestionado por el fabricante de motores y turbinas español ITP Aero, IMDEA Materiales colaboró en el desarrollo de la carcasa de la turbina de presión intermedia (IPT) del UltraFan. El demostrador del motor UltraFan® es la base

IMDEA Materiales da la bienvenida al nuevo investigador postdoctoral MSCA Carlos Ruestes

El Instituto de IMDEA Materiales dio la bienvenida a un nuevo investigador postdoctoral financiado por las Acciones Marie Skłodowska-Curie en agosto con la incorporación del Dr. Carlos Ruestes. El Dr. Ruestes se embarcará en el ambicioso proyecto MeNaWir para estudiar las propiedades mecánicas de

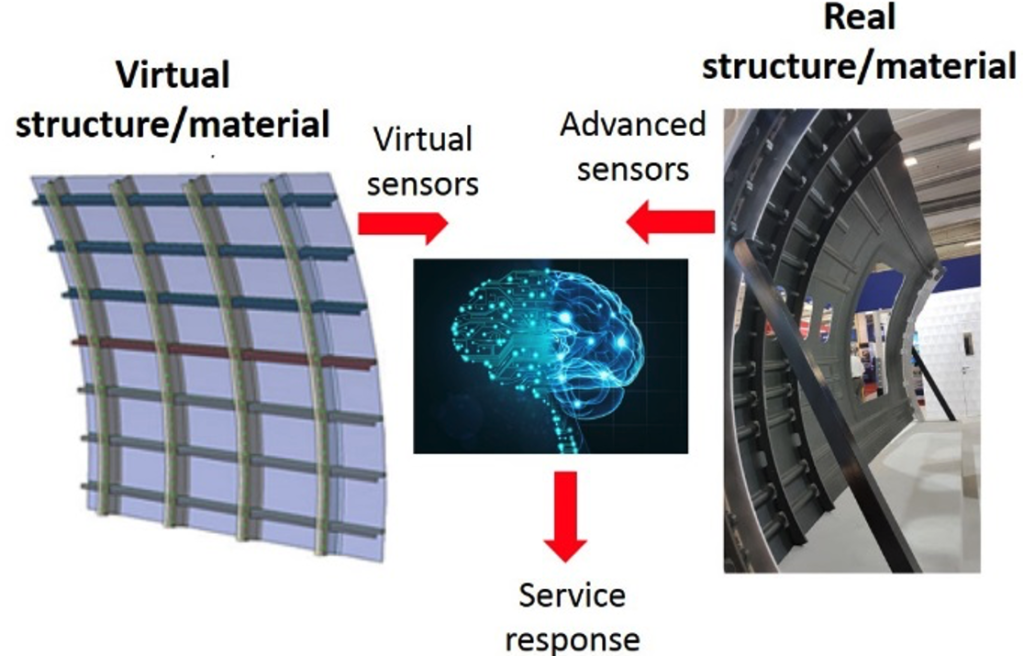

IMDEA Materiales contribuye al desarrollo de la próxima generación de sensores inteligentes para aviación

Como parte del proyecto DOMMINIO de la Unión Europea, el Instituto IMDEA Materiales está ayudando a crear sensores inteligentes integrados que proporcionarán a los ingenieros en tierra información actualizada en tiempo real sobre las aeronaves durante el vuelo. Estos sensores se instalarán por 3D

Alumni en el punto de mira – La Dra. Bárbara Bellón

La Dra. Bárbara Bellón ha visto de primera mano lo rápido que ha crecido la reputación internacional de IMDEA Materiales en los últimos años. Bellón, que actualmente trabaja en el Instituto Max Planck para la Investigación del Hierro en Düsseldorf, realizó su doctorado en el centro de

Highly efficient electromagnetic wave absorption Fe-MOF-rGO based composites with enhanced flame retardancy

(DAMAS) DESIGN OF MASTER ALLOYS FOR SINTERED STEELS

Project details Funding: Public-Private Partnership 2021.Project coordinator: AMES SinteringProject period: 01/09/2022 – 30/11/2025 IMDEA Materials' researchers Dr. José Manuel Torralba Dr. Damien Tourret Abstract The aim of this project is to provide a way for AMES

Shape-stable and smart polyrotaxane-based phase change materials with enhanced flexibility and fire-safety

Seminario del Prof. Alan Luo, de la Universidad Estatal de Ohio y Director del “Laboratorio de Investigación de Fabricación y Materiales Ligeros”, titulado: “Lightweight materials and sustainable manufacturing: the role of ICME”. El día 5 de septiembre, a las 12:00, en la Sala de Seminarios.

Abstract: Lightweight materials including aluminum, magnesium and titanium alloys and metal matrix composites are increasingly being used in the transportation and manufacturing industries to reduce energy consumption and carbon footprint. Emerging materials including high entropy alloys,

Un Madrileño y «una nueva era espacial»

El investigador del Instituto IMDEA Materiales, Juan de Pablos Gómez, no puede recordar exactamente cuándo surgió su interés por los confines del universo más allá de nuestro pequeño rincón de la Vía Láctea. Es algo con lo que asume haber nacido. Posiblemente desde su infancia, Pero desde su

Antoine Jerusalem

Professor Antoine Jerusalem joined IMDEA Materials in 2008 following the completion of his post-doctorate at the Massachusetts Institute of Technology (MIT). He spent four years at IMDEA Materials as leader of the Computational Mechanics of Materials Group, with a focus on the modelling of a wide

Fast-charging and long-lasting Mg-Na hybrid batteries based on extremely pseudocapacitive bronze TiO2 nanosheet cathodes

El director científico de IMDEA Materiales, Javier Llorca, habla con la Cadena Ser sobre los avances en implantes biodegradables.

El profesor Javier LLorca habla con el periodista David Callejo sobre el trabajo del Instituto IMDEA Materiales en el desarrollo de una nueva generación de implantes biodegradables que pueden cambiar de forma. Puede escuchar esta fascinante entrevista en el siguiente enlace:

Highly Oriented Direct-Spun Carbon Nanotube Textiles Aligned by In Situ Radio-Frequency Fields

Effects of Processing Parameters on the Microstructure and Mechanical Properties of Nanoscaled WC-10Co Cemented Carbide

Correlation between Microstructure and Mechanical Properties of Heat-Treated Novel Powder Metallurgy Superalloy

La Razón y Telemadrid entre los que destacan el lanzamiento del proyecto BIOMET4D.

El periódico La Razón y la cadena de televisión Telemadrid son dos de los medios que han cubierto el lanzamiento del nuevo proyecto BIOMET4D, financiado por Horizonte Europa y el Consejo Europeo de Innovación. La iniciativa de 3,5 millones de euros para desarrollar implantes inteligentes,

Andrés Sierra recibe el premio a la mejor presentación oral en la FF&W 2022

IMDEA Materiales felicita a Andrés Sierra Soraluce que ayer fue galardonado con la mejor presentación oral en la Conferencia de Fatiga, Fractura y Desgaste (FF&W) 2022. El trabajo de Sierra Soraluce en IMDEA Materiales se centra en el método de tratamiento térmico “quenching and partitioning”

Cytotoxicity Assessment of Surface-Modified Magnesium Hydroxide Nanoparticles

Seminario del Dr. Ivan Fernández, de Nano4Energy, titulado: « Actividades de investigación y desarrollo en Nano4Energy: del desarrollo a escala de laboratorio de láminas delgadas a producción industrial». El día 8 de septiembre, a las 12:00, en la Sala de Seminarios.

Resumen: Nano4Energy es una empresa de base tecnológica de gran proyección internacional. La actividad principal de Nano4Energy es el desarrollo tecnológico de recubrimientos de alto valor añadido mediante la tecnología de “sputtering” magnetrón y la implementación de dichos recubrimientos en

IMDEA Materiales liderará un proyecto Pathfinder de €3,5 millones financiado por el EIC para desarrollar implantes inteligentes biodegradables que cambian de forma

- El proyecto BIOMET4D tiene como objetivo crear una nueva generación de implantes biodegradables capaces de cambiar de forma y de soportar cargas para la restauración dinámica de tejidos, con el fin de proporcionar mejoras en el tratamiento de la craneosinostosis y en los procedimientos de

Unveiling the reinforcement effects in cottonseed protein/polycaprolactone blend biocomposites

La química de las poesías – El Mundo

El Diario de Castilla y León de El Mundo habla con la investigadora Carmen Martínez Alonso del Instituto IMDEA Materiales sobre recibir una prestigiosa beca Fulbright, su trabajo en catálisis y la economía del hidrógeno y su pasión por la literatura y la poesía.

Alicia Moya Cuenca

Dr Alicia Moya Cuenca was born in Cuenca, Spain. She joined IMDEA Materials in 2013, where she completed her PhD thesis entitled “Hybrid systems based on metal oxide and nanocarbons: electronic properties and applications for photocatalysis” under the supervision of Dr. Juan J. Vilatela. Afterwards,

El Instituto IMDEA Materiales aplica metodologías innovadoras en la automatización de la tomografía computarizada

El investigador Jonathan Espinoza destaca que la automatización de la tomografía computarizada de rayos X (XCT) representa una oportunidad clara para reducir costes y ahorrar tiempo tanto a nivel industrial como en investigación. Espinoza cuenta con una beca del Programa de Empleo Juvenil de la

Criteria for slip transfer across grain and twin boundaries in pure Ni

Criteria for slip transfer across grain and twin boundaries in pure Ni

Alumni en el punto de mira – El Dr. Antoine Jerusalem

El Dr. Antoine Jerusalem admite que fue una apuesta arriesgada unirse al recientemente creado Instituto de Materiales IMDEA en 2008, pero no le cabe duda de que su audaz apuesta resultó más que rentable. Jerusalem, en la actualidad Profesor de Ingeniería Mecánica en la Universidad de Oxford, fue

Development of powders of Ti-Fe-Sn ultrafine eutectics for laser additive manufacturing

El Instituto IMDEA Materiales busca una nueva generación de implantes biodegradables para mejorar los resultados clínicos

El investigador de IMDEA Materiales Guillermo Domínguez desarrolla nuevas aleaciones de zinc para fabricar stents cardiovasculares biodegradables de mejores prestaciones que los actuales del mercado.El objetivo final de este trabajo es obtener una aleación de este material que se utiliza en técnicas

(BIOMET4D) Smart 4D BIOdegradable METallic Shape-shifting Implants for Dynamic Tissue Restoration

Project details Funding: Horizon Europe. EIC Pathfinder Open 2021 (Project No 101047008)Project coordinator: IMDEA MaterialsProject period: 01/07/2022 – 30/06/2026 IMDEA Materials' researchers Dr. Jennifer PattersonDr. Jon Molina-AldareguiaDr. Javier

La investigadora Carmen Martínez Alonso del Instituto IMDEA Materiales ha sido reconocida con una beca Fulbright

Sin duda, una de las grandes esperanzas en la transición hacia una movilidad más sostenible son las celdas de combustible de hidrógeno. Las celdas de combustible de hidrógeno generan energía eléctrica mediante el proceso de reacción de reducción de oxígeno, que combina el hidrógeno y el oxígeno

Seminario del Dr. Jesús Ordoño de la IGTP, titulado: «Lactate as a novel signal for cardiac tissue engineering and regenerative medicine». El día 26 de julio, a las 12:00, en la Sala de Seminarios.

Resumen: The increasing prevalence of cardiovascular diseases on the world population urge the development of efficient new therapies for the reestablishment of the cardiac function. The heart has a very limited regenerative ability, and so lost cardiomyocytes cannot be replaced, thus causing

A Machine Learning Strategy for Race-Tracking Detection During Manufacturing of Composites by Liquid Moulding

Icosahedral quasicrystal enhanced nucleation in commercially pure Ni processed by selective laser melting

DELIGHTED holds fourth progress meeting

The DELIGHTED consortium held its fourth online progress meeting. Project partners presented and discussed their research activities from last 6 months, as well as preparation of deliverables. The research plans for the next 6 months were updated.

IMDEA Materiales: Una Perspectiva Internacional

La necesidad de ir más allá de su propia región en la búsqueda de talento científico es uno de los principales motores de las colaboraciones internacionales de IMDEA Materiales con universidades y centros de investigación de diferentes partes del mundo. Estas colaboraciones han hecho que el

A novel highly efficient intumescent flame-retardant polypropylene: Thermal degradation, flame retardance and mechanism

DELIGHTED researchers continue dissemination activities

The DELIGHTED members continue to actively disseminate the outcomes of the project. Dr. Alexandros Banis from University of Gent has participated in the 19th International Conference on Strength of Materials (ICSMA) 2022 in Metz, France, on June 27 – July 1, 2022. The ICSMA is the premier

Alumni en el punto de mira – La Dra. Francisca Martínez-Hergueta

La Dra. Francisca Martínez-Hergueta ha destacado el entorno positivo de trabajo e investigación que ofrece el Instituto IMDEA Materiales como una de sus características más atractivas para los investigadores actuales y futuros. Martínez-Hergueta pasó cinco años en el IMDEA Materiales, de 2011 a

Francisca Martínez-Hergueta

La Dra. Francisca Martínez Hergueta se incorporó a IMDEA Materiales en 2011 donde realizó su doctorado en Ingeniería de Estructuras, Cimentaciones y Materiales supervisado por el Prof. Carlos González y el Prof. Javier Llorca. Presentó su tesis titulada "Análisis multiescala del comportamiento

A review on carbon-based phase change materials for thermal energy storage

Publicamos Nuestro Informe Anual 2021

Estamos encantados de anunciar el lanzamiento del informe 2021 de IMDEA Materiales. El documento completo se puede visualizar y descargar aqui. Este informe anual está diseñado para dar una visión general del Instituto y los principales logros en 2021. Además, se ha incluido una

Influence of hybridisation on energy absorption of 3D woven composites under low-velocity impact loading. Modelling and experimental validation

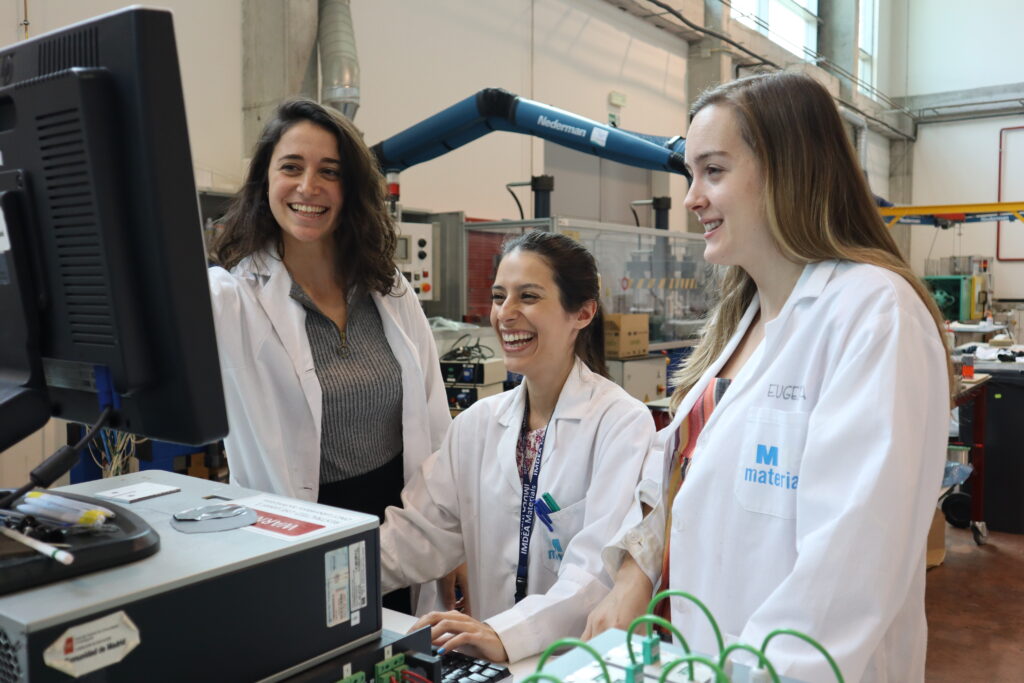

“Un soplo de aire fresco”: El Instituto IMDEA Materiales celebra el Dia Internacional de la Mujer en la Ingeniería

Alrededor de 35% de los investigadores predoctoral y postdoctoral en el instituto IMDEA Materiales son mujeres.Una de ellas, la investigadora predoctoral Eugenia Nieto, ha subrayado el papel importante de las mujeres en la ingeniería, destacando la importancia en la investigación de poder ver las

Particle size effects in ductile composites: An FFT homogenization study

La ingeniera que colgó las botas por amor a la ciencia – ABC.es

Hoy, en el Día de la Mujer en la Ingeniería, nuestra investigadora Lola Martín Alonso habla con el Diario ABC sobre su difícil decisión de dejar un contrato profesional con el Real Madrid para seguir una carrera científica en el Instituto IMDEA Materiales, la importancia de promover una mayor

Defensa de Doctorado de Ignacio López titulada “Hierarchical Microstructures to Overcome the Conflict Between Strength and Toughness of Hard Coatings: Tin/Ni as a Model System” – 21 de junio de 2022.

La Defensa de Doctorado tendrá lugar el 21 de junio a las 5:00 pm en la Universidad de Texas en Arlington. Será de forma online. La disertación se titula “Hierarchical Microstructures to Overcome the Conflict Between Strength and Toughness of Hard Coatings: Tin/Ni as a Model System”. Ha sido

Seminario del Dr. Kendell Pawelec de la Universidad del Estado de Michigan, titulado: «Engineering Materials for the Translation of Biomedical Devices». El día 27 de junio, a las 11:00 am, en la Sala de Seminarios.

Resumen: The goal of regenerative medicine is to control an individual’s healing response after trauma, working at the cellular level to repair damaged tissue. However, to successfully intervene in tissue repair, there must be a basic understanding of the types of signals cells receive from their

Micromechanical characterization of the material response in a PA12-SLS fabricated lattice structure and its correlation with bulk behavior

Giacomo Villa presents DELIGHTED at ESSC&DUPLEX

The DELIGHTED members continue to disseminate the outcomes of the project. Giacomo Villa from POLIMI has participated in the 11th European Stainless Steel Conference Science & Market and the 7th European Duplex Stainless Steel Conference & Exhibition (ESSC&DUPLEX) in Bardolino, Verona,

Effect of printing direction and thickness on the mechanical behavior of SLM fabricated Hastelloy-X

José Manuel Torralba, ganador de la Medalla Ivor Jenkins 2022

El Director del Instituto IMDEA Materiales, José Manuel Torralba es el ganador de la Medalla de Ivor Jenkins 2022, el premio internacional más prestigioso del mundo en el ámbito de la pulvimetalurgia. El. Profesor Torralba es el segundo español en recibir este reconocimiento después del Dr.

De la ciencia en las nubes a los CNT: El viaje de un investigador del programa MSCA al Instituto IMDEA Materiales

Para el observador externo, la dinámica de la formación de las nubes y la producción de fibras de alto rendimiento pueden parecer dos campos científicos muy poco relacionados. Pero en el mundo de la nanotecnología, la ciencia fundamental que subyace al estudio de las gotas de agua y los

First Year Assessment de Ángela Castro, titulado «Alveolar-Capillary Membrane Chip: a new perspective for the study of lung diseases»- 17 de junio, 2022 – 12:00 pm.

Resumen: The current global pandemic (COVID-19) and other recent major epidemics, including SARS and MERS and the historical Spanish flu, are caused by respiratory viruses that affect the lung. To better understand the pathophysiology of these diseases and develop preventive and therapeutic

Ultrahigh strength, modulus, and conductivity of graphitic fibers by macromolecular coalescence

El Mundo destaca el trabajo de IMDEA Materiales en el campo de la medicina regenerativa

Prótesis impresas en 3D a medida de cada paciente e implantes curativos que se disuelven sin dejar rastro una vez que han hecho su trabajo. ¿Suena a ciencia ficción? El diario El Mundo ha publicado un artículo sobre el importante e innovador trabajo que IMDEA Materiales está realizando en el

El futuro de la fabricación aditiva se expone en IMDEA Materiales

El instituto IMDEA Materiales ha acogido a algunos de los principales centros de investigación y socios industriales del país en una jornada técnica sobre fabricación aditiva. La jornada, organizada por MATERPLAT y la Red de Excelencia en Fabricación Aditiva READI, contó en su primera sesión con

Biomass-based coating from chitosan for cotton fabric with excellent flame retardancy and improved durability

IMDEA Materiales trabaja para reducir la contaminación por plásticos marinos en el Día Mundial de los Océanos 2022

- Según la ONU, cada año se producen más de 400 millones de toneladas de residuos plásticos en el mundo, de los cuales entre 9 y 14 millones de toneladas llegan a los océanos. - Los nuevos materiales poliméricos sostenibles de base biológica que está desarrollando IMDEA Materiales están

El Instituto IMDEA Materiales y una nueva generación de compuestos reciclables con estructura sándwich

El Dr. Lin Xuebao, investigador postdoctoral en IMDEA Materiales financiado por el programa Marie Sklodowska-Curie (MSCA), destaca la libertad que se ofrece a los investigadores como uno de los mayores puntos fuertes del Instituto. El Dr. Lin señala que esa libertad podría dar lugar a avances

High-energy sodium-ion hybrid capacitors through nanograin- boundary-induced pseudocapacitance of Co(3)O(4)nanorods

La ciencia de los materiales en «la punta de la lanza» para afrontar los retos medioambientales

El Instituto IMDEA Materiales celebra el Día Mundial del Medio Ambiente 2022 y el papel vital de la ciencia de los materiales en los avances tecnológicos sostenibles El desarrollo del instituto de nuevos aceros inoxidables martensíticos ligeros ayudarán a cumplir las normativas de emisiones de

Surface engineering for cellulose as a boosted Layer-by-Layer assembly: Excellent flame retardancy and improved durability with introduction of bio-based “molecular glue”

Seminario del Dr. Raymundo Arróyave de la Universidad de Texas A&M, titulado: «Towards 3D+ Printing of Metals and Alloys». El día 3 de junio, a las 12:00 pm, en la Sala de Seminarios.

Resumen: The current paradigm that guides many materials and manufacturing research is to optimize a materials’ (hierarchical) structure to accomplish a specific function and then assemble different components made with different materials into ever more complex arrangements in order to realize

Dr. Ahad Mohammadzadeh, investigador postdoctoral MSCA y la próxima generación de superaleaciones

El deseo de Ahad Mohammadzadeh de extender sus alas más allá de su ciudad natal, Tabriz, Irán, le llevó a solicitar una beca postdoctoral de las Acciones Marie Sklodowska-Curie (MSCA). Y en su tiempo en el Instituto IMDEA Materiales como investigador postdoctoral financiado por el programa, el

Determination of Rate-Dependent Properties in Cohesive Frictional Materials by Instrumented Indentation

DELIGHTED researchers begin dissemination activities

DELIGHTED researchers have begun dissemination activities. Dr. Aniruddha Dutta (OCAS), Mohamed Elkot (MPIE) and Giacomo Villa (Polytech Milano) participated in the 5th International High Manganese Steel Conference (HMnS) 2022 organized in Linz, Austria, on May 23-25, 2022. The HMnS is the only

Defensa de Doctorado de Álvaro Doñoro titulada “Baterías estables de litio-azufre mediante ingeniería de electrodos e interfaces” – 17 de junio de 2022.

La Defensa de Doctorado tendrá lugar el 17 de junio, a las 11:00 hr, en el Salón de Grados (Módulo 8) de la Facultad de Ciencias de la Universidad Autónoma de Madrid (Cantoblanco). La disertación se titula “Stable lithium-sulfur batteries through electrode and interface engineering”. Ha sido

Seminario del Prof. Jesús Ruiz de la Universidad Politécnica de Madrid, titulado: «Residual stresses and hydrogen embrittlement». 13 de julio, a las 12:00 pm, en la Sala de Seminarios.

Abstract: Residual stresses are those that remain in the material after external loads have been removed. To satisfy static equilibrium, they are self-equilibrating. Residual stresses are generated as a response of the material to inhomogeneous permanent inelastic strains. The latter will induce

Flexible, thermostable and flame-resistant epoxy-based thermally conductive layered films with aligned ionic liquid-wrapped boron nitride nanosheets via cyclic layer-by-layer blade-casting

Quantitative investigation of the influence of electrode morphology in the electro-chemo-mechanical response of li-ion batteries.

IMDEA Materiales abre nuevos caminos en el cálculo de diagramas de fase

Como investigadora postdoctoral financiada por el programa Marie Sklodowska-Curie (MSCA), la Dra. Sha Liu está ayudando a que el Instituto se convierta en una referencia mundial en la metodología de los diagramas de fase. Liu, de 31 años, se unió a IMDEA Materiales en 2018 gracias a una ayuda

Defensa de la Tesis de Clara Galera titulada «Fundamentals of solidification during selective laser melting of aerospace alloys” – 24 de mayo de 2022.

La Defensa Doctoral tendrá lugar el 24 de mayo a las 11:00 am en la «Sala Verde» (José Echegaray) de la Escuela de Caminos, Canales y Puertos de la UPM. La disertación se titula «Fundamentals of solidification during selective laser melting of aerospace alloys». Ha sido supervisada por el Prof.

IMDEA Materiales acoge el primer foro de investigación e innovación en el que participan gestores de la Ciencia e Innovación de todas las comunidades autónomas españolas

Cerca de 30 representantes de Consejerías de Ciencia e Innovación de todo el país visitaron el Instituto IMDEA Materiales en Getafe en la primera jornada de trabajo. IMDEA Materiales fue elegido por la Comunidad de Madrid como ejemplo del compromiso de la región con la investigación y la innovación.

Resilient moth-eye nanoimprinted antireflective and self-cleaning TiO2 sputter-coated PMMA films

Being a Marie Skłodowska-Curie postdoctoral fellow at IMDEA Materials

Are you interested in applying for a Marie Skłodowska-Curie Postdoctoral Fellowship (MSCA PF)? Want to know what it's like to be an MSCA PF fellow in our Institute? Join us in this webinar on June 1st at 12:00 hours (Madrid time) and learn more about the hosting offers we have for call 2022 of

Portevin-Le Chatelier Effect in a Powder Metallurgy Co-Ni-Based Superalloy

Microcellular foams production from nanocomposites based on PS using MOF nanoparticles with enhanced CO2 properties as nucleating agent

IMDEA Materiales celebra el Dia de Europa y emprende camino a la Noche Europea de los Investigadores de Madrid 2022

IMDEA Materiales ha dado la bienvenida a estudiantes de la UC3M como parte de las actividades organizadas dentro del proyecto La Noche Europea de los Investigadores de Madrid El Director del Instituto, el Prof. José Manuel Torralba, ha señalado que estos proyectos son cruciales para trasladar a

Selective laser melting of a Fe-Si-Cr-B-C-based complex-shaped amorphous soft-magnetic electric motor rotor with record dimensions

First Year Assessment de Moises Zarzoso, titulado «Machine Learning-based Structural Health Monitoring of Composites»- 19 de mayo, 2022 -11:30 hr.

Resumen: Neural networks are able to approximate nonlinear functions with accuracy. This makes them suited for many fields far from their origin in computer science.In this work we will apply these neural networks to composite materials from two different perspectives: top-down, for structural

First Year Assessment de Moises Zarzoso, titulado «Machine Learning-based Structural Health Monitoring of Composites»- 13 de mayo, 2022 -12:00 hr.

Resumen:

Ofertas de acogida para las becas postdoctorales Marie Skłodowska-Curie 2022

Buscamos investigadores postdoctorales que quieran solicitar una beca postdoctoral (PF) de las Acciones Marie Skłodowska-Curie (MSCA) en la convocatoria 2022. Nuestro Instituto tiene un largo historial de acogida de fellows MSCA y ha obtenido excelentes tasas de éxito en las últimas convocatorias de

A generalized line tension model for precipitate strengthening in metallic alloys

Seminario del Dr. Monsur Islam del Instituto de Tecnología de Microestructuras, Instituto de Tecnología de Karlsruhe, titulado: «3D shaping of carbon to engineered living carbon materials ». 31 de mayo, a las 12:00 pm, en la Sala de Seminarios.

Resumen: Carbon microelectromechanical system (carbon MEMS) has emerged as a technique alternative to silicon-based MEMS technologies in the last two decades. Although carbon-MEMS allows for the fabrication of 3D carbon microstructures useful for several applications, complex architectures are

Defensa de Tesis Doctoral de Yanyan Duan titulado «Perovskite for hybrid light emitting devices» – 4 de mayo, 2022.

La Defensa Doctoral tendrá lugar el 4 de mayo a las 10:30 hr. La asistencia será a modo remoto: https://short.upm.es/t3l99 La disertación se titula « Perovskite for hybrid light emitting devices». Fue supervisado por el Prof. Dr. Rubén D. Costa y el Prof. Dr. De-Yi Wang.

Machine learning-aided design of composite mycotoxin detoxifier material for animal feed