Nanostructured Silicon anodes for Lithium-ion batteries

IMDEA Materials has a proprietary method to produce continuous sheets of nanostructured Silicon [1] (see Fig. 1) and their integration as high capacity anodes in Lithium-ion batteries without use of processing solvents or polymers. The electrodes combine high capacity (> 6 mAh/cm2), high

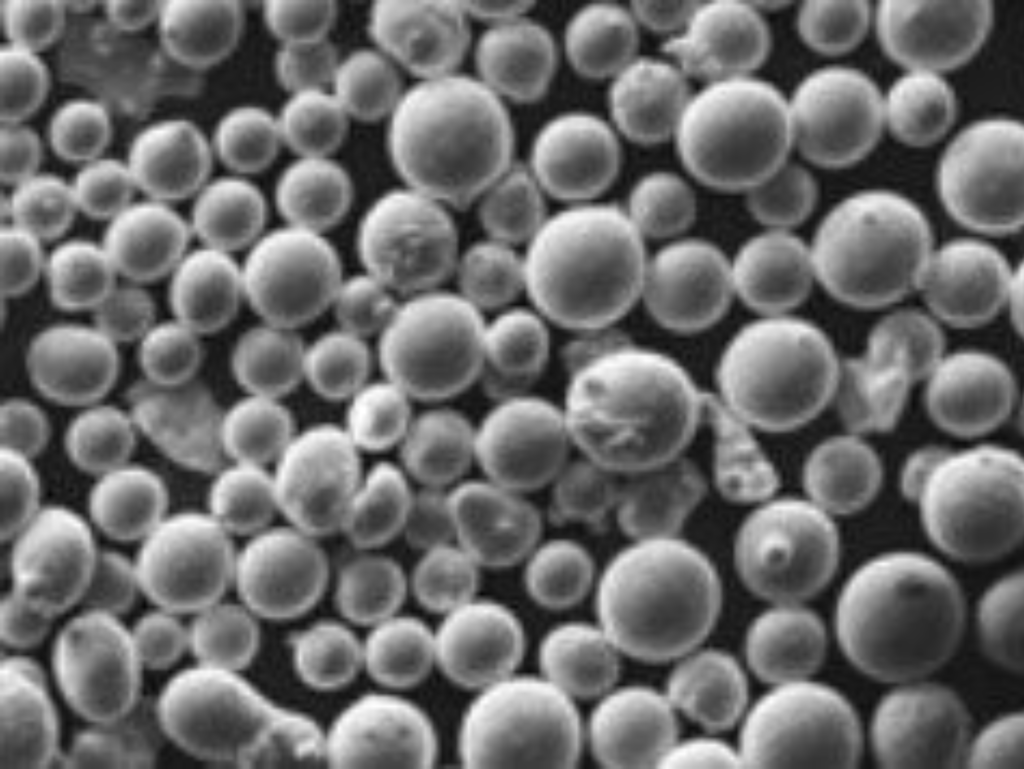

Development of competitive high-entropy alloys using commodity powders

(MULTI-FAM) DEVELOPMENT OF MULTI-MATERIAL AND MULTIFUNCTIONAL 3D PARTS THROUGH ADDITIVE MANUFACTURING ASSISTED BY INTELLIGENT MATERIAL AND PROCESS DESIGN

Funding: Ministerio de Ciencia e Innovación. Retos Colaboración 2019 Region: National Project period: 2020 – 2022 Partners: ArcelorMittal (Project Coordinator), AIMEN, IMDEA Materials Institute Principal Investigator: Damien Tourret (damien.tourret@imdea.org) The MULTI-FAM project proposes

DELIGHTED holds second progress meeting

The second online progress meeting was held on June 22, 2021. Project partners presented and discussed their research activities within the last 6 months, as well as preparation of deliverables. The research plans for the next 6 months were updated.

Fast and Accurate Machine Learning Strategy for Calculating Partial Atomic Charges in Metal-Organic Frameworks

First Year Assessment of Lucia Cobian, entitle «Experimental-Numerical Analysis of Polymer Based Lattice Materials Fabricated with Additive Manufacturing» – 24th of June, 2021, a las 12:00 pm.

Resumen: Lattice materials are materials constituted by the repetition of small cells composed of structural units as bars, beams or shells, which form a lattice. The cell geometry can be designed to have an outstanding macroscopic response such as very high specific stiffness or energy

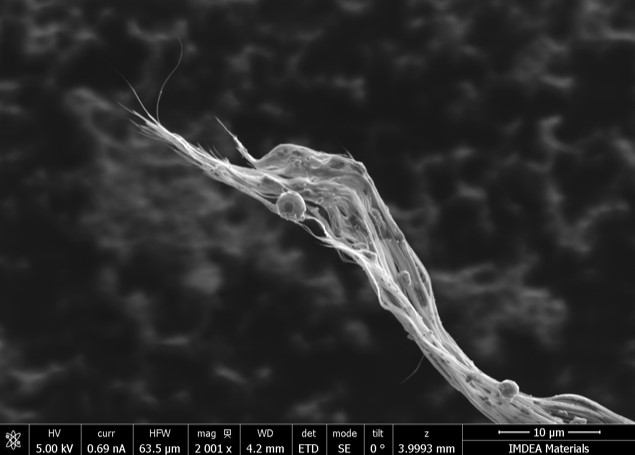

First Year Assessment de Isabel Gómez titulado «Synthesis and Characterization of inorganic nanowires via Floating Catalyst Chemical Vapour Deposition»- 12:00 pm, 25 de Junio, 2021.

Resumen: The work presented is the result of a year studying the growth of inorganic nanowires by floating catalyst chemical vapour deposition (FCCVD) with the objective of applying this technique to the synthesis of metal oxide nanowires. The differences between substrated-CVD and FCCVD

Calorimetric and Dielectric Investigations of Epoxy-Based Nanocomposites with Halloysite Nanotubes as Nanofillers

Defensa de Tesis Doctoral de Rodrigo Santos titulado «Analysis of precipitation hardening in metallic alloys by means of dislocation dynamics» – 21 de junio, 2021.

La Defensa Doctoral tendrá lugar el 21 de junio a las 11:30 pm en la "Sala Verde" de la Escuela de Caminos, Canales y Puertos de la UPM. La disertación se titula "Analysis of precipitation hardening in metallic alloys by means of dislocation dynamics". Ha sido supervisada por el Dr. Javier

Defensa de Tesis Doctoral de Mario Rueda titulado «Experimental and computational micromechanics of fibre-reinforced polymer composites at high strain rates» – 25 de junio, 2021.

La Defensa Doctoral tendrá lugar el 25 de junio a las 12:00 pm en la "Sala Verde" de la Escuela de Caminos, Canales y Puertos de la UPM. La disertación se titula "Experimental and computational micromechanics of fibre-reinforced polymer composites at high strain rates" Ha sido supervisada por

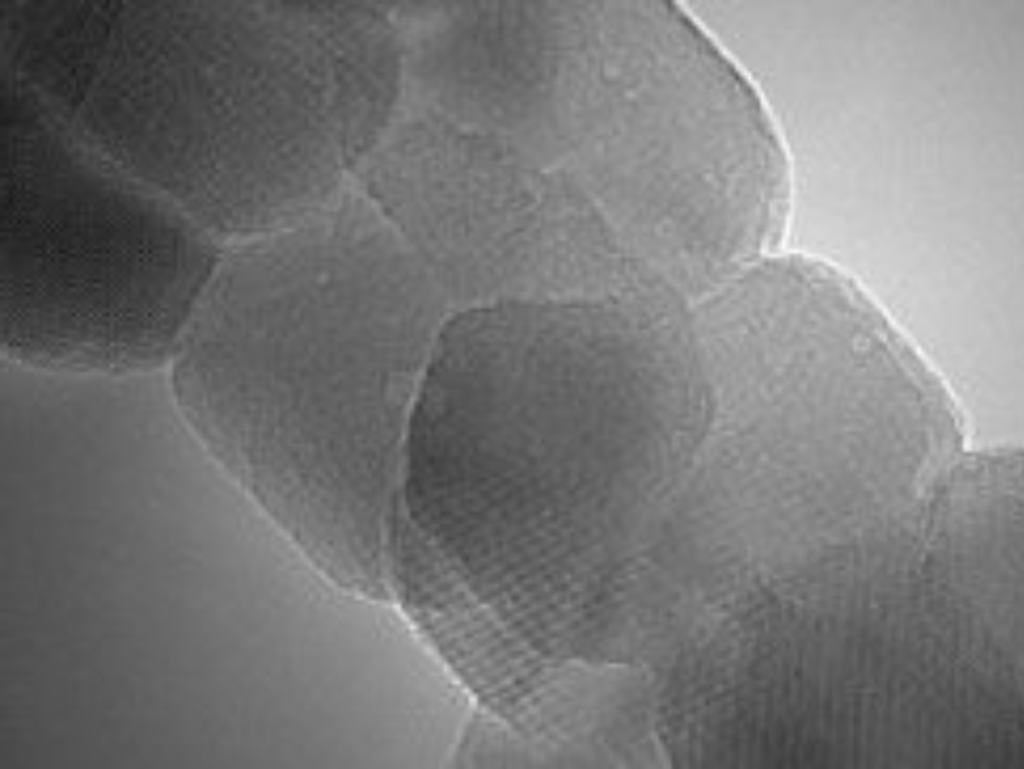

Highly efficient BiVO4 single-crystal nanosheets with dual modification: phosphorus doping and selective Ag modification

Machine learning with persistent homology and chemical word embeddings improves prediction accuracy and interpretability in metal-organic frameworks

High temperature in situ SEM assessment followed by ex situ AFM and EBSD investigation of the nucleation and early growth stages of Fe-Al intermetallics

Dislocation dynamics prediction of the strength of Al-Cu alloys containing shearable θ ′ ′ precipitates

Metal organic frameworks enabled rational design of multifunctional PEO-based solid polymer electrolytes

A multiplicative finite strain crystal plasticity formulation based on additive elastic corrector rates: Theory and numerical implementation

Jose Manuel Torralba, elegido nuevo Director

El pasado 27 de abril, una vez concluido un proceso de selección internacional, el Prof. José Manuel Torralba fue nombrado Director del Instituto IMDEA Materiales por el Patronato del centro. El Prof. Torralba sustituye al Prof. Ignacio Romero, que ha estado al frente del Instituto durante los

Ofertas de acogida para las becas postdoctorales Marie Skłodowska-Curie 2021

Buscamos investigadores postdoctorales interesados en solicitar una beca postdoctoral Marie Skłodowska-Curie (MSCA PF) en la convocatoria 2021. Nuestro Instituto tiene una larga trayectoria acogiendo a fellows MSCA y ha obtenido excelentes tasas de éxito en las últimas convocatorias MSCA PF. Las

Photoelectrocatalytic detection of NADH on n-type silicon semiconductors facilitated by carbon nanotube fibers

Effect of ZrH2 particles on the microstructure and mechanical properties of IN718 manufactured by selective laser melting

Novel Phosphorous-Based Deep Eutectic Solvents for the Production of Recyclable Macadamia Nutshell-Polymer Biocomposites with Improved Mechanical and Fire Safety Performances

Novel Phosphorous-Based Deep Eutectic Solvents for the Production of Recyclable Macadamia Nutshell-Polymer Biocomposites with Improved Mechanical and Fire Safety Performances

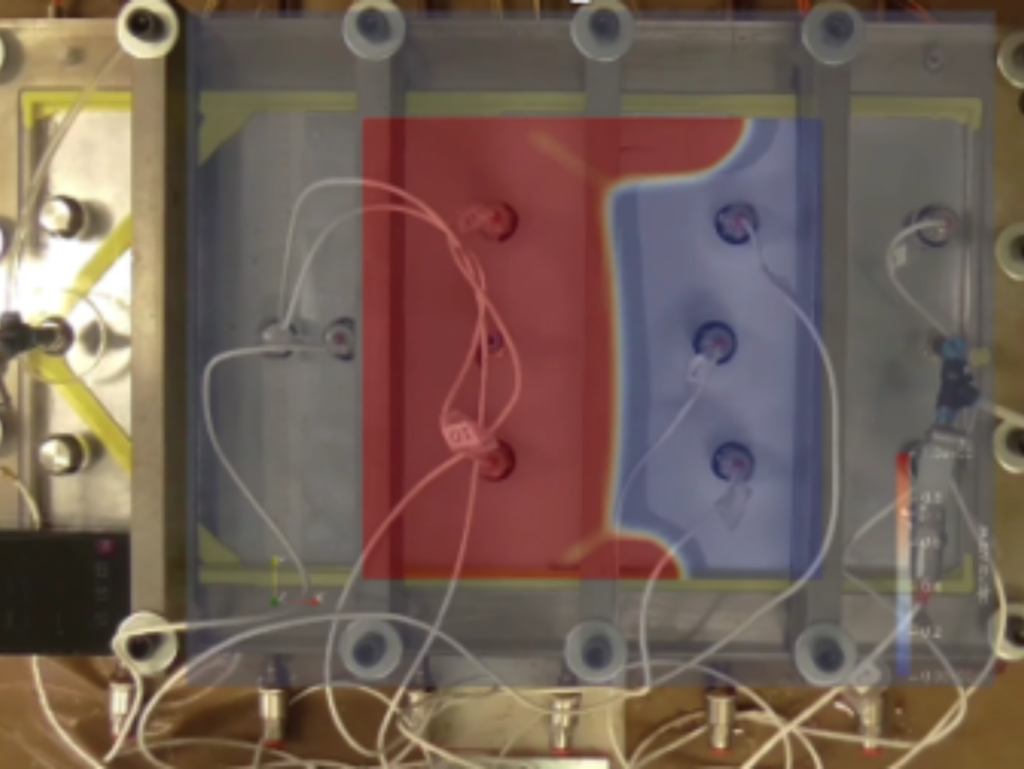

First Year Assessment de Keayvan Keramati titulado «Race Tracking Study during RTM and predict it with machine learning by CFD generated data»- 28 de Mayo, 2021, a las 11:00 am.

Resumen: Resin transfer molding (RTM) is a closed-mold procedure in the composite manufacturing process. The resin enters the mold from the inlet port, and the gradient pressure of the inlet and outlet makes the flow move into the mold. A common disturbance that happened during the process is

Surface functionalization of carbon fabric towards high-performance epoxy composites via enhanced fiber-matrix interfacial strength and intergrowth charring behavior

Chlorite oxidized oxyamylose differentially influences the microstructure of fibrin and self assembling peptide hydrogels as well as dental pulp stem cell behavior

Rationally designed zinc borate@ZIF-8 core-shell nanorods for curing epoxy resins along with low flammability and high mechanical property

Conferencia IMDEA Materiales – KIST 2021

El próximo 25 de mayo organizamos una conferencia conjunta con el Instituto de Ciencia y Tecnología de Corea para explorar oportunidades de colaboración en el campo de los materiales compuestos.

Post-processing effects on microstructure, interlaminar and thermal properties of 3D printed continuous carbon fibre composites

Rationally designed zinc borate@ZIF-8 core-shell nanorods for curing epoxy resins along with low flammability and high mechanical property

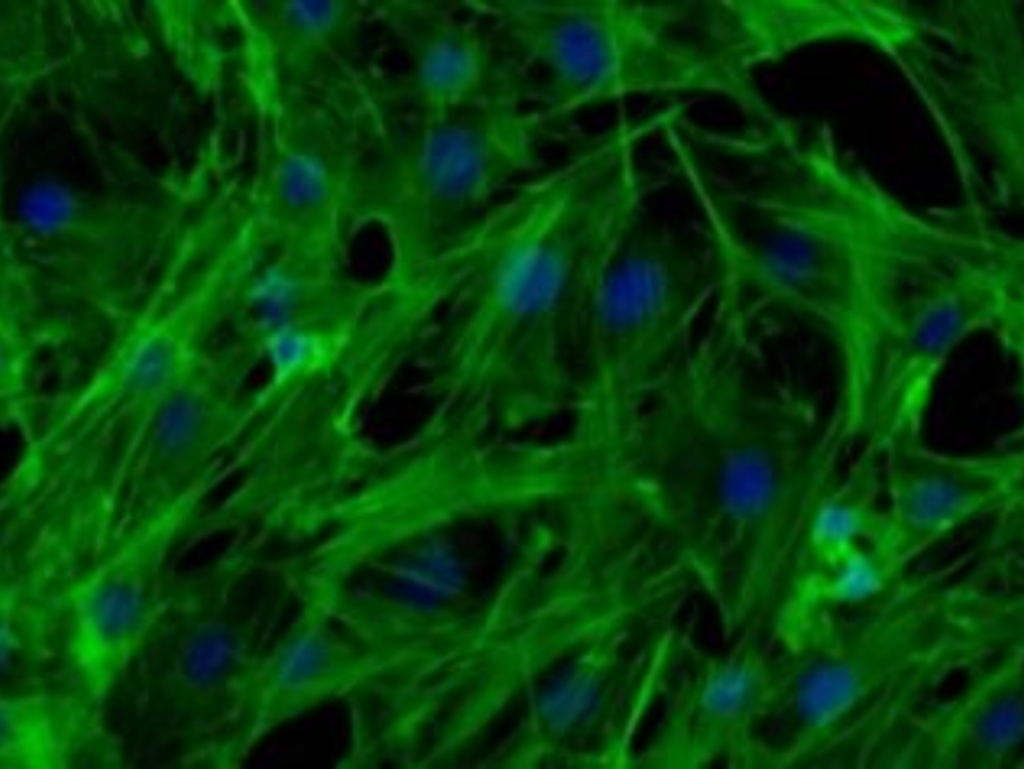

Materiales para Salud

OBJETIVO Y VISIÓN El Programa de Materiales para Salud busca desarrollar nuevas estrategias basadas en materiales, que aborden diversos retos en medicina, desde el tratamiento de daños en órganos o tejidos hasta la mejora de los sistemas de liberación de fármacos. El

Post-processing effects on microstructure, interlaminar and thermal properties of 3D printed continuous carbon fibre composites

Processing and properties of long recycled-carbon-fibre reinforced polypropylene

Preface – Virtual Special Issue on nanomechanical testing in materials research and development

«2nd PhD Meeting» de IMDEA Materiales

¿Quieres desarrollar tu carrera en el ámbito de la ciencia y la innovación? ¿Te gustaría hacer tu Doctorado en una investigación más aplicada y cercana al mercado? ¡Ven a ver los proyectos en los que podrías trabajar con nosotros el próximo 6 de Febrero!

Andrea Fernández, considerada “Influencer 20.0”.

¡Nuestra compañera Andrea Fernández, considerada “Influencer 20.0”! Ha sido protagonista de esta consideración gracias a su investigación para ayudar a los demás y tratar de hacer un mundo mejor. En el siguiente link podréis ver toda la información al igual que el video donde le hacen una

Varios científicos de IMDEA Materiales en el «Ranking of the World Scientists: World’s Top 2% Scientists»

La Universidad de Standford acaba de publicar su "Ranking of the World Scientists: World´s Top 2% Scientists". El ranking, que analiza datos de Scopus como el número de artículos publicados, el impacto de las citas a lo largo de la carrera hasta finales de 2019 y el impacto de las citas durante el

Spatial inhomogeneity, interfaces and complex vitrification kinetics in a network forming nanocomposite

High-throughput nanoindentation mapping of cast IN718 nickel-based superalloys: influence of the Nb concentration

Experimental and numerical analysis of cyclic deformation and fatigue behavior of a Mg-RE alloy

Dimensionally reduced nonlinear solids with general loads and constitutive laws: Theory and finite element formulation for rod-like bodies

Promotion of the flame retardancy of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide grafted natural rubber using expandable graphite

Effect of Vinylene Carbonate Electrolyte Additive on the Surface Chemistry and Pseudocapacitive Sodium-Ion Storage of TiO2 Nanosheet Anodes

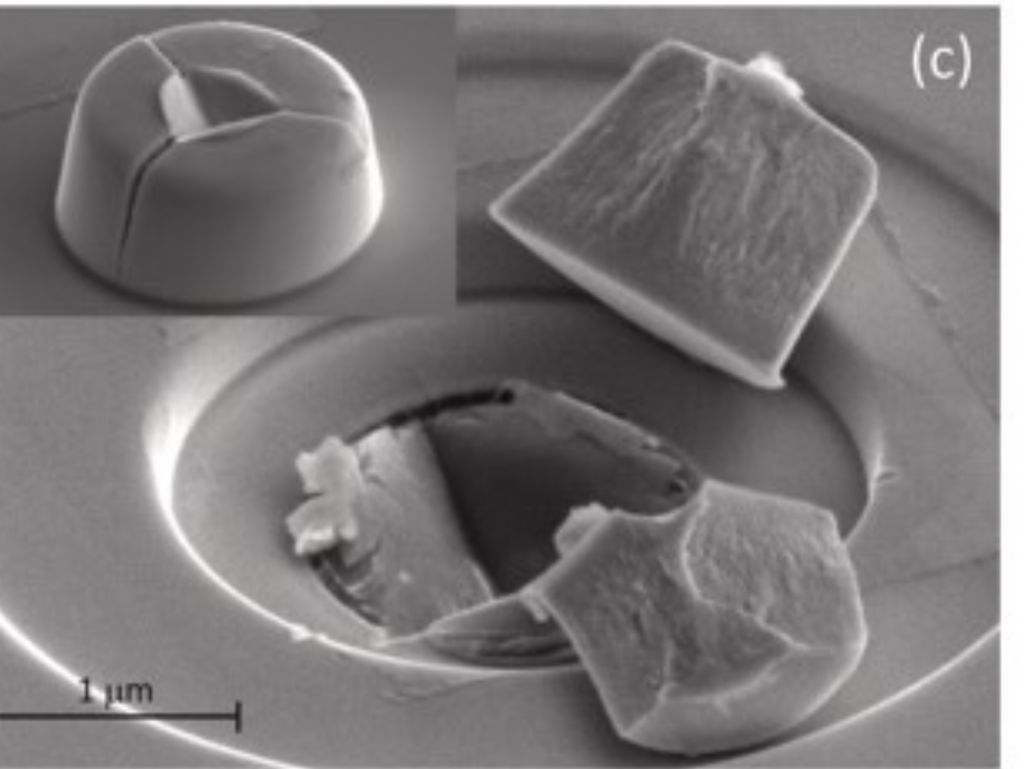

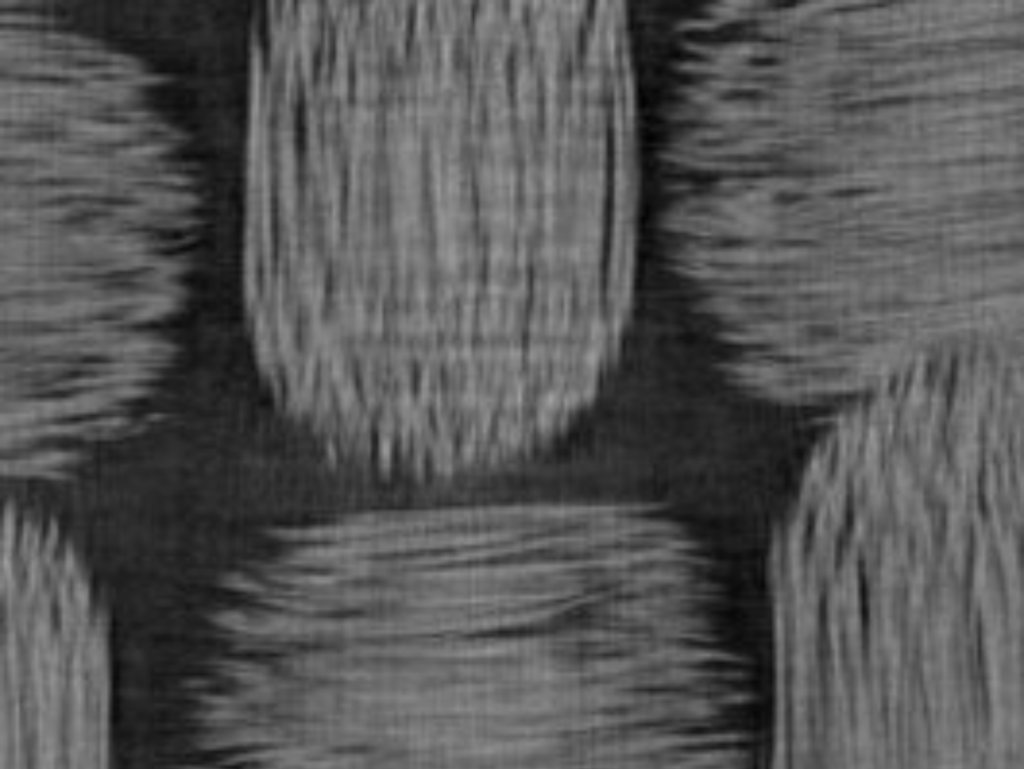

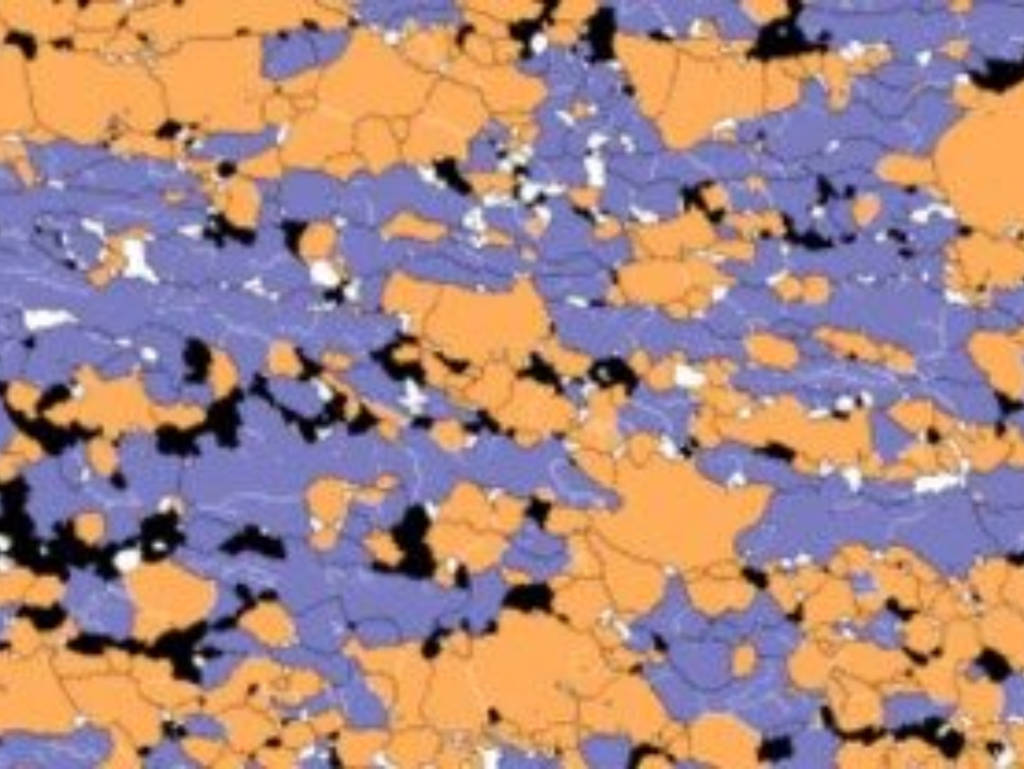

Ganadores del 9º y 10º concurso de imágenes científicas de IMDEA Materiales

Ya conocemos a los ganadores de la 10ª edición del concurso de imagen científica de IMDEA Materiales. Este año las mejores imágenes fueron: Categoría de caracterización Con los brazos abiertos, Monica Echeverry Categoría de simulación:Interfaces sólido-líquido de dendritas de Al-Cu

Laser-Guided Corrosion Control: A New Approach to Tailor the Degradation of Mg-Alloys

Seminario del Prof. Dan Mordehai de Technion (Facultad de Ingeniería Mecánica), titulado «Microstructure-based Plasticity of Metals – Going from the Atomic to the Continuum Scale» – 22 de abril a las 12:00 pm en el Auditorio.

Resumen: Microstructural defects on the atomic level are known to be responsible to the macroscopic deformation of metals. Despite, the study of microstructure-based plasticity of metals is still a great challenge owing to the multiphysics and multiscale nature of plasticity. In this talk, I will

Low-energy consumption, free-form capacitive deionization through nanostructured networks

The effect of microstructure and strain rate on the 25 °C and 700 °C compression deformation behavior of powder metallurgy processed Ti-45Al-2Nb-2Mn (at.%)-0.8 TiB2 (vol%) alloy

Nanomechanical behavior of single taper-free GaAs nanowires unravelled by in-situ TEM mechanical testing and molecular dynamics simulation

Ciencia «made in Madrid», élite mundial

La ciencia que se realiza en la Comunidad de Madrid se encuentra en la élite mundial, gracias en parte a los investigadores de los Institutos IMDEA. Más información en este artículo del diario ABC.

Basalt Fiber-Based Flame Retardant Epoxy Composites: Preparation, Thermal Properties, and Flame Retardancy

Materiales para pseudo-satélites de alta altitud

Comenzamos a colaborar con la start-up madrileña SmartHAPS para investigar materiales de aplicación en pseudo-satélites de alta altitud (HAPS por sus siglas inglesas). Estos vehículos aéreos constituyen una excelente alternativa a la operación de los satélites y los drones aéreos. La investigación

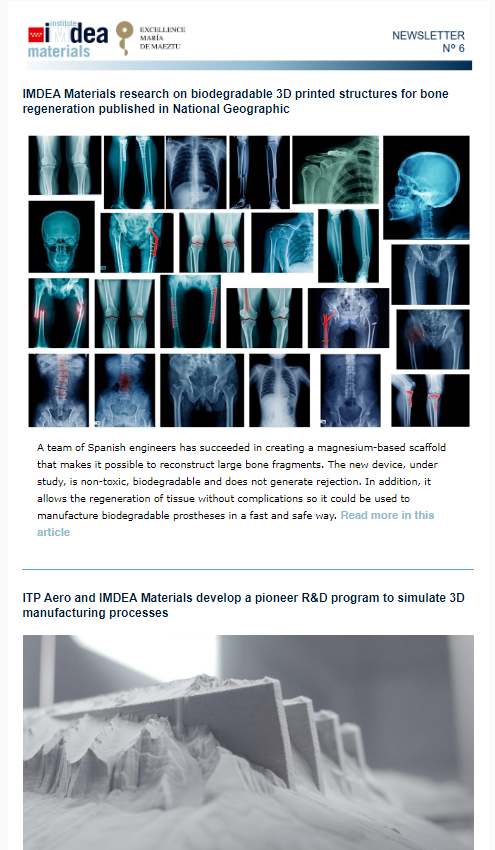

Alumni Newsletter Nº 6

Click in the image to access the full newsletter

Macroscopic yarns of FeCl3-intercalated collapsed carbon nanotubes with high doping and stability

3D-printed resistive carbon-fiber-reinforced sensors for monitoring the resin frontal flow during composite manufacturing

A facile and robust route to polyvinyl alcohol-based triboelectric nanogenerator containing flame-retardant polyelectrolyte with improved output performance and fire safety

Multiscale prediction of microstructure length scales in metallic alloy casting

Advanced lightweight materials for fire safety and energy efficient structures

Sandwich-structured composites are the most reliable and effective technology for weight reduction of interior panels in the transportation industry. However, the properties and manufacturing processes of sandwich composites are limited by the characteristics and mechanical properties of the

The effect of microstructure and strain rate on the 25 °C and 700 °C compression deformation behavior of powder metallurgy processed Ti-45Al-2Nb-2Mn (at.%)-0.8 TiB2 (vol%) alloy

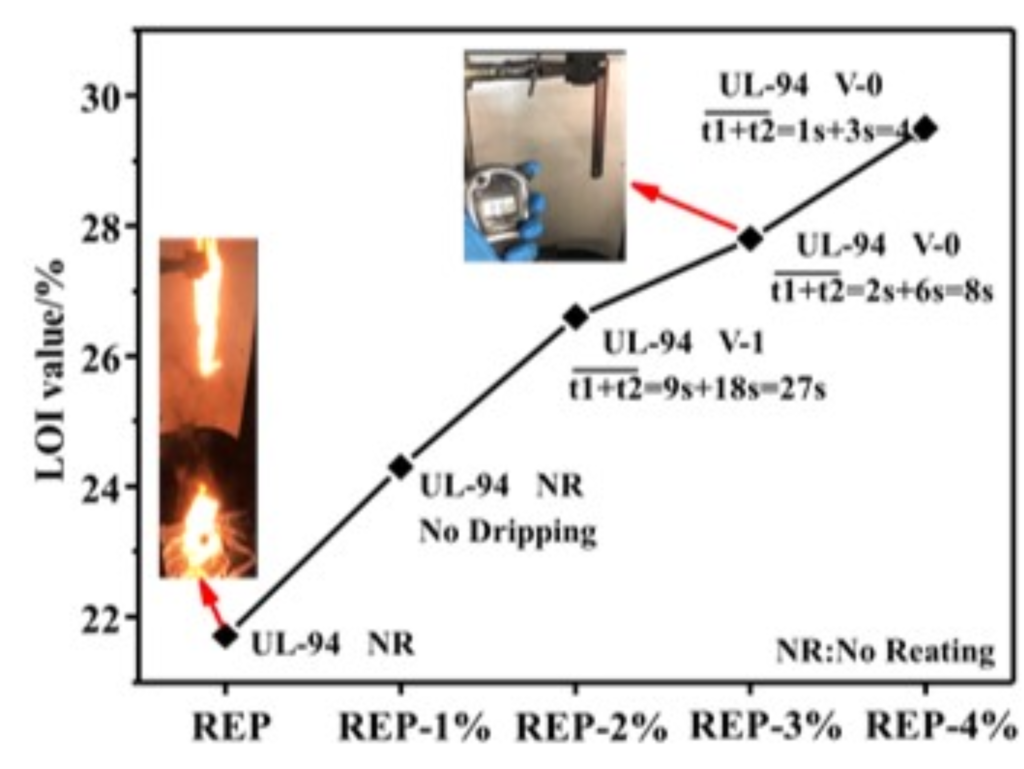

Fire retardant reprocessable epoxy-based composites

IMDEA Materials has developed a technology to produce Reprocessable Epoxy Resin (REP) composites with excellent fire retardancy and re-processability. Compared with pure epoxy resin with a Limited Oxygen Index (LOI) of 21.7 % and no rating in vertical burning test (UL-94), recyclable epoxy resin

Nanomechanical behavior of single taper-free GaAs nanowires unravelled by in-situ TEM mechanical testing and molecular dynamics simulation

3D-printed resistive carbon-fiber-reinforced sensors for monitoring the resin frontal flow during composite manufacturing

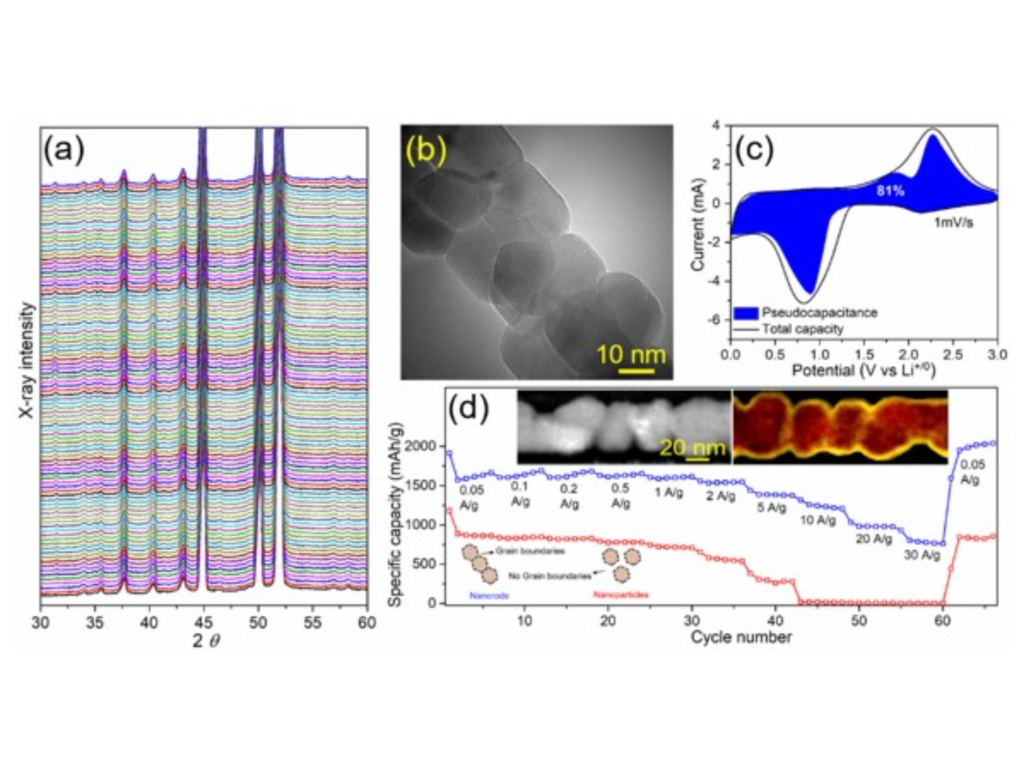

Defect-engineered electrodes

Although secondary Li-ion batteries are widely used for electrochemical energy storage, low energy (100-300 Wh kg-1) and power density (250-400 W kg-1) are limiting their applications in several areas including long-range electric vehicles. This is mainly due to the use of graphite anodes with low

Bioinspired antireflective flexible films with optimized mechanical resistance fabricated by roll to roll thermal nanoimprint

In-situ studies of defect-engineered electrodes

Diffusion independent pseudocapacitive ion storage is one of the recently investigated mechanisms for achieving ultrafast Li and Na-ion storage. It usually involves surface/ near surface charge-transfer reactions. Nevertheless, intrinsic pseudocapacitance of transition metal oxide anodes is not

Precipitate strengthening of pyramidal slip in Mg-Zn alloys

New 3D-printed alloys for extreme conditions

IMDEA Materials has recognized expertise on the design of alloys for high temperature, high strength and lightweight applications, which are suitable for the production of 3D printed components by laser-based or binder-jetting methods. Previous works include the design of superalloys for turbine

Development of segregations in a Mg-Mn-Nd alloy during HPT processing

IMDEA Materials Institute Alumni Interview – Saeid Loftian

Dr. Saeid Loftian was born in Iran. He joined IMDEA Materials in 2010, where he completed his PhD thesis entitled "High-Temperature Mechanical Behavior of Al/SiC Nanoscale Multilayers" under the supervision of Dr. Jon Molina and Prof. Javier LLorca. The thesis was awarded with the best PhD Thesis

Controlled Nucleation and Growth of Carbon Nitride Films on CNT Fiber Fabric for Photoelectrochemical Applications

Stress-induced α″ martensitic phase transformation and martensitic twinning in a metastable β titanium alloy

Auto Draft

Synthesis and integration of nanomaterials (nanotubes, nanofibers and hybrids) Synthesis of nanocarbon/semiconductor hybrids for photo and electrocatalysis, interaction of nanocarbons with liquid molecules, polyelectrolytes and inorganic salts.Sensors: chemical, piezoresistive,

Thermophysical properties of porous Ti2AlC and Ti3SiC2 produced by powder metallurgy

Seis equipos de investigación, incluyendo al grupo MNG de IMDEA Materiales, obtienen financiación del Carbon Hub

Carbon Hub, la iniciativa de investigación cero-emisiones de la Universidad de Rice, ha otorgado seis subvenciones semilla para seis proyectos que permitirán avanzar rápidamente su visión para transformar el sector del petróleo y el gas en un sector líder, proveedor tanto de energía proveniente de

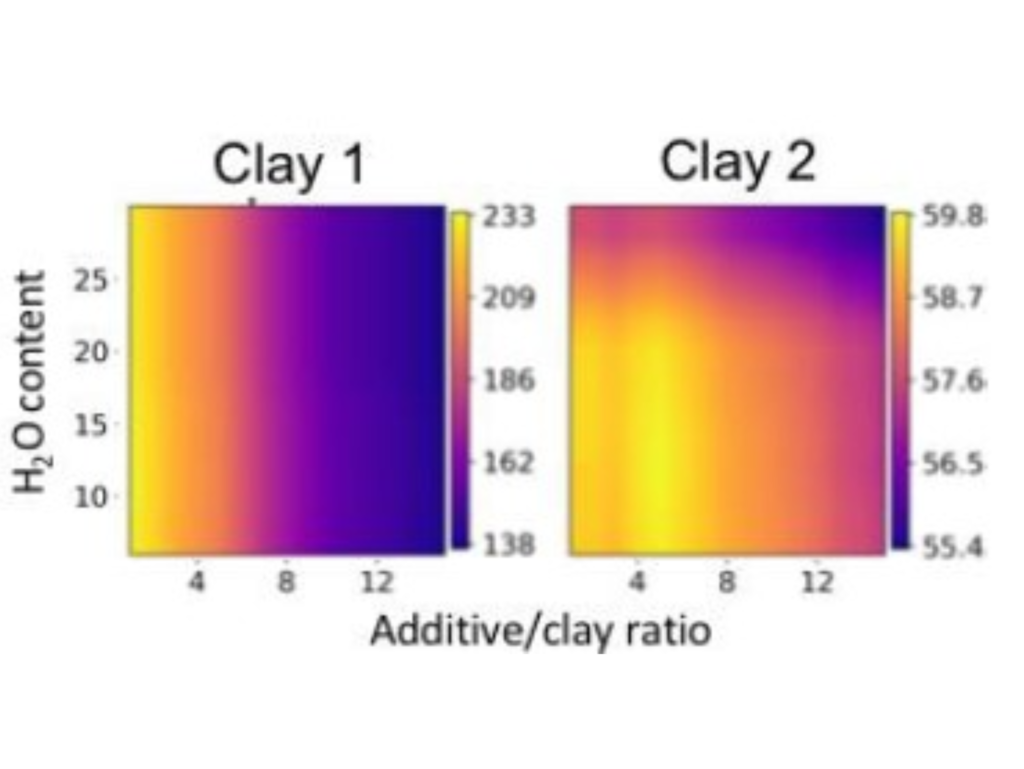

Accelerated product development via AI-guided material design and chemical processes optimization

IMDEA Materials has know-how in developing data-driven experimentation workflows that exploit machine learning algorithms to minimize the number of experiments involved in the development of materials tuned to specific applications and/or the chemical processes governing their synthesis and

Escucha lo que hacen las mujeres en ciencia para mejorar nuestras vidas

Nuestra compañera María Teresa Pérez Prado y otras investigadoras explican lo que hacen para mejorar nuestras vidas en esta entrevista grabada por la cadena SER en IMDEA Energía con el motivo del Día Internacional de la Mujer 2021.

Strategy and algorithms for the parallel solution of the nearest neighborhood problem in shared-memory processors

Virtual testing of metals

IMDEA Materials offers a mature, fully stand-alone technology able to predict the mechanical response of an engineering alloy as function of its microstructure [1]. This technology is able to provide the anisotropic elastic properties and stress-strain elastoplastic curves, the creep response and

Energy-momentum conserving integration schemes for molecular dynamics

Construction of a novel three-in-one biomass based intumescent fire retardant through phosphorus functionalized metal-organic framework and beta-cyclodextrin hybrids in achieving fire safe epoxy

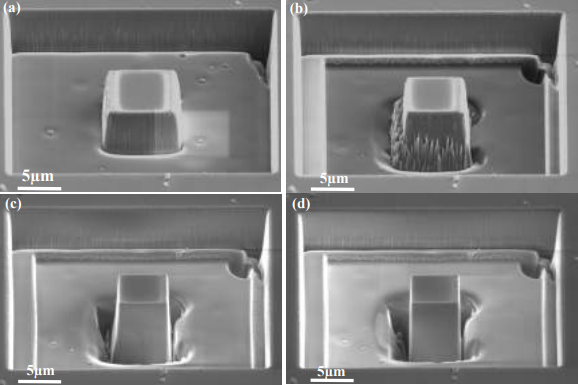

Scientific Highlight: New coatings for extreme conditions

Titanium aluminum nitrides (TiAlN) are currently the most versatile coatings in terms of performance with various applications in industry: as wear-resistant coatings for cutting tools; for increasing productivity in die casting, reducing soldering and retarding fire cracks; for plastic processing,

Computational Modeling of Dislocation Slip Mechanisms in Crystal Plasticity: A Short Review

First Year Assessment de Andres Sierra titulado «Microstructural design in novel stainless steels via quenching and partitioning to improve their mechanical properties»- 12 de Marzo, 2021.

Resumen: The quenching and partitioning (Q&P) process is a relatively new heat treatment (2003) aimed at the creation of a multi-phase microstructure of tempered martensite and stabilized retained austenite. This microstructure enhances the mechanical properties of the steel, achieving an

Multiscale in-situ characterization of materials and processes

Current trends to reduce weight, energy consumption and improve functionality are leading to new materials with complex microstructures, whose behavior can only be understood from the synergetic contribution of processes occurring at multiple length scales (from nm to m). Examples of these materials

Iron Oxide-Iron Sulfide Hybrid Nanosheets as High-Performance Conversion-Type Anodes for Sodium-Ion Batteries

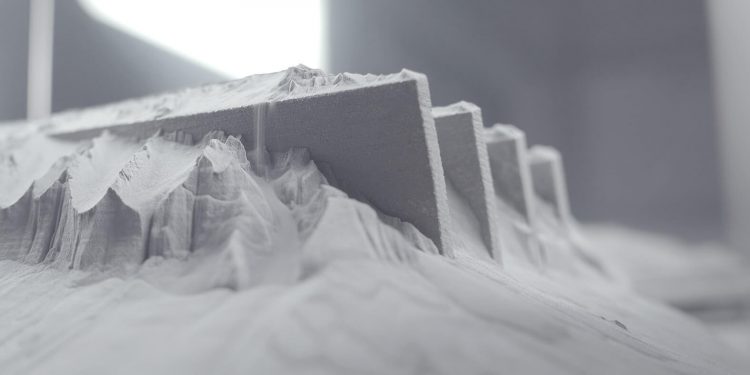

Scientific Highlight: Bioresorbable scaffolds for tissue engineering

IMDEA Materials has developed technologies to manufacture scaffolds made of biodegradable polymers (PCL, PLA, PLGA, etc), biodegradable metals (Mg and Zn) and their composites for tissue engineering (see Fig. 1 below). The main advantage of this technology is that it allows designing scaffolds with

Dimensionally reduced nonlinear solids with general loads and constitutive laws: Theory and finite element formulation for rod-like bodies

Nanoindentation of Amorphous Carbon: a combined experimental and simulation approach

Scientific Highlight: Physical simulation of joining of dissimilar materials

IMDEA Materials has developed a physical simulation tool to predict joinability of dissimilar metallic materials with different melting points. Very small samples of the actual dissimilar materials are subjected to the same thermal and mechanical profiles in a thermo-mechanical simulator (GLEEBLE

Mechanical and morphological properties of poly(3-hydroxybutyrate)-thermoplastic starch/clay/eugenol bionanocomposites

Corrosion behavior of diverse sputtered coatings for the helium cooled pebbles bed (HCPB) breeder concept

Scientific Highlight: Ultrafast processing of advanced metallic materials

IMDEA Materials has developed technologies for ultrafast processing of advanced metallic materials in a thermo-mechanical simulator (GLEEBLE 3800). They allow to precisely control the thermo-mechanical processing at high heating/cooling rates, as well as at high strain rate plastic deformation.

Modelling and simulation of Hydrogen embrittlement

Europe’s commitment to reach carbon neutrality by 2050 is strongly pushing renewable energy sources and hydrogen has emerged as a versatile and environmentally friendly mean to store and transport clean energy. The large-scale usage of hydrogen has prompted new challenges in the core electrochemical

Microstructure, mechanical properties, corrosion resistance and cytocompatibility of WE43 Mg alloy scaffolds fabricated by laser powder bed fusion for biomedical applications

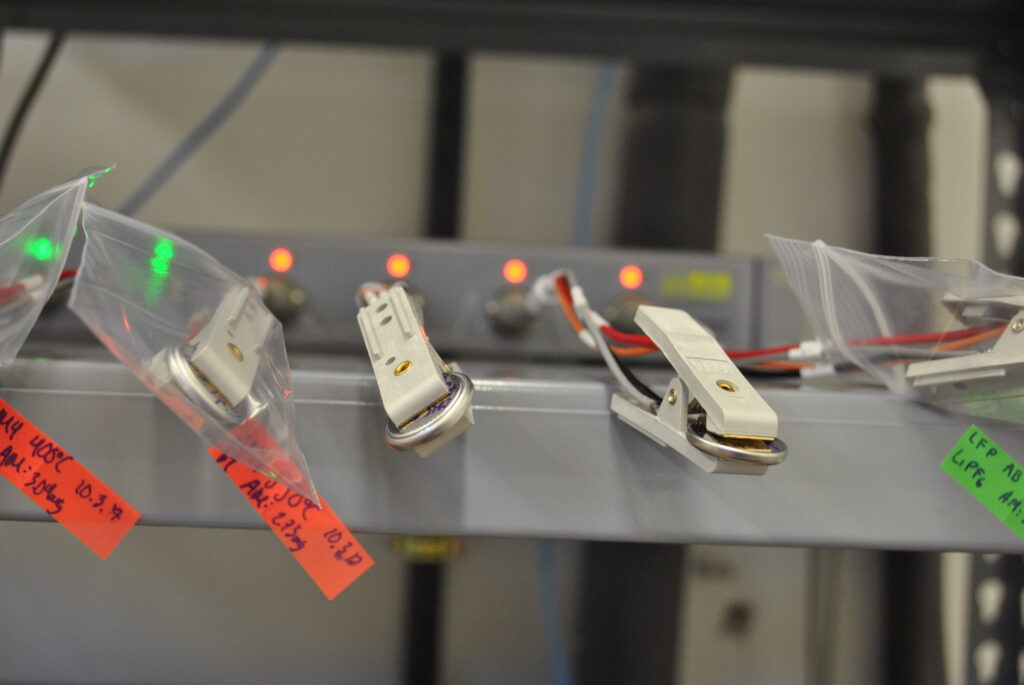

Fire retardant battery materials

IMDEA Materials is working on new battery materials that combine electrochemical integrity and enhanced fire safety. Fig. 1 below shows a fully solid-state battery based on a HKUST-1 MOF modified electrolyte with simultaneously improved electrochemical performance and fire safety was successfully

Xiang Ao

(FUNMAT) Functionally Metalized Nanocellulose For Future Smart Materials

Funding: H2020. Marie Skłodowska-Curie Actions Individual Fellowships Region: European Project period: 2021 – 2024 Principal Investigator: Dr. Ahmed Said Azizi Samir (ahmed.azizisamir@imdea.org) Designing at the nanoscale is a promising and challenging strategy to innovate new building-block

On the crystallographic anisotropy of plastic zone size in single crystalline copper under Berkovich nanoindentation

Éxito en la convocatoria 2020 de las becas individuales Marie Skłodowska-Curie

Hemos obtenido una beca individual Marie Skłodowska-Curie en la convocatoria 2020 y otras 2 propuestas están muy arriba en la lista de reserva. Nuestro centro presentó un total de 7 propuestas, que han recibido puntuaciones en el rango 98.4 - 79.2. La puntuación de todas ellas está por por encima

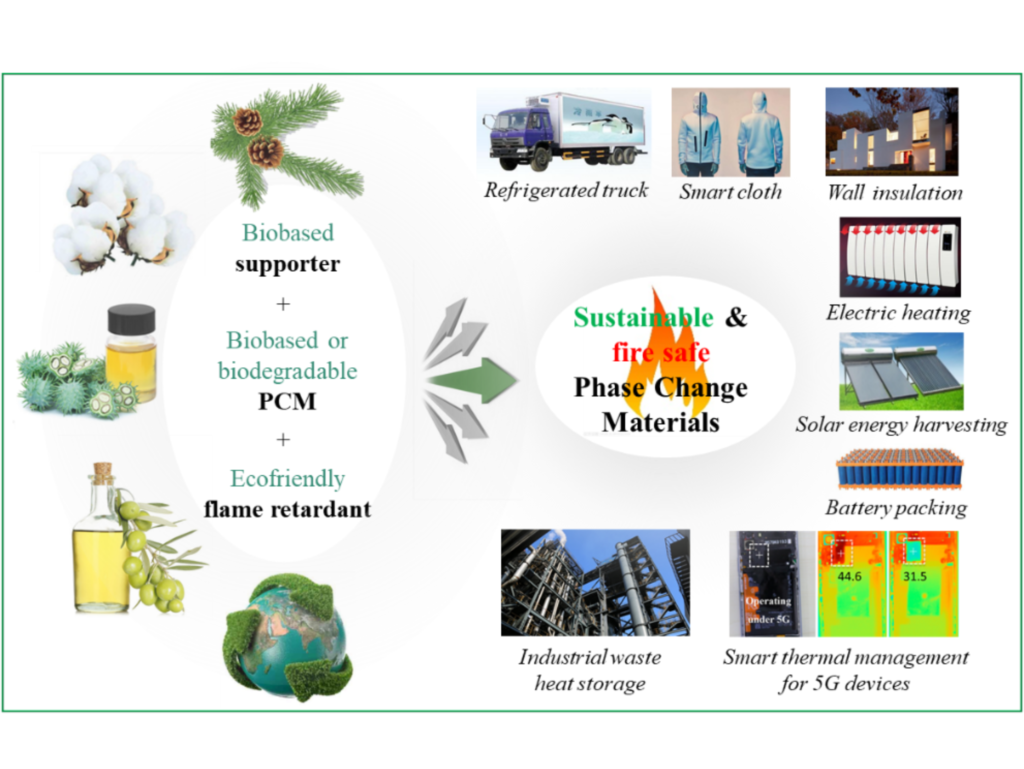

Sustainable, fire safe phase change materials

IMDEA Materials can design and prepare novel Phase Change Materials (PCMs) for thermal energy storage applications that: are prepared in an easy and green pathway and, at the same time, have high mechanical performance, fire safety, form stability, phase transition enthalpy, and thermal

Extremely pseudocapacitive interface engineered CoO@3D-NRGO hybrid anodes for high energy/ power density and ultralong life lithium-ion batteries

Low heat yielding electrospun phosphenanthrene oxide loaded polyacrylonitrile composite separators for safer high energy density lithium-ion batteries

Javier LLorca habla sobre nuevos materiales para prótesis óseas

Javier LLorca habla de nuevos materiales para prótesis óseas en el programa de radio de RTVE de píldoras de divulgación científica "El laboratorio de JAL". Sigue el enlace y escucha la primera píldora para conocer más sobre este candente tema de investigación (contenido solo disponible en

3D printing of structural composites by using recycled fibers

Due to the rapid growth in the use of composite materials, environmental concerns have become an increasingly influential topic, making recyclability of composite materials a key issue. Furthermore, several related EU laws have been passed to minimize the environmental impact of composite structures

Ultrafine eutectic Ti-Fe-based alloys processed by additive manufacturing – A new candidate for high temperature applications

(Europa Redes y Gestores) Oficina de Proyectos Europeos IMDEA Materiales

Funding: Ministerio de Ciencia, Innovación y Universidades. Europa Redes y Gestores - Europa Centros Tecnológicos 2020Region: NationalProject period: 2021 – 2022Principal Investigator: Miguel Ángel Rodiel (miguel.angel.rodiel@imdea.org) Grant aimed at providing research organizations with the

Predictive simulation of metal Additive Manufacturing – from composition & processing to mechanical properties

As part of its strategic initiative on damage-tolerant additive manufacturing, IMDEA Materials develops a suite of physics-based computational models and simulation tools aimed at linking processing, microstructures and properties, in order to accelerate the discovery and deployment of new alloys

Fabrication and Characterization of PEEK/PEI Multilayer Composites

First Year Assessment de Alvaro Méndez titulado «Harder and tougher AlTi(B)N coatings deposited by HiPIMS for high temperature applications» – 1 de febrero, 2021, a las 12:00.

Abstract: A novel series of multilayered nanocomposite materials based on the AlTiN system with high Al content and the addition of B as the successful element for obtaining the amorphous phase are presented. The coatings were grown using co-deposition reactive HiPIMS from an alloyed TiAl(X)

On the improvement of properties of bioplastic composites derived from wasted cottonseed protein by rational cross-linking and natural fiber reinforcement

AI-guided smart manufacturing of structural composites

Manufacturing in the EU is crucial, given that it is one of the main drivers in innovation, job creation and sustainable growth. It involves almost 2,000,000 companies that provide approximately 28.5 million jobs. Therefore, its impact is significant in terms of economic share, with it being ~18% of

(DOMMINIO) Digital method for improved manufacturing of next-generation multifunctional airframe parts

Project details Funding: H2020. Smart, green and integrated transport (SC4) Project coordinator: AIMEN Project period: 01/01/2021 – 30/06/2024 Website: http://www.domminioproject.eu/ IMDEA Materials' researchers Dr. Carlos Daniel González Dr. Juan José Vilatela Abstract DOMMINIO aims

Exploring the correlation between solvent diffusion and creep resistance of Mg-Ga HCP alloys from high throughput liquid-solid diffusion couple

Comparing mesoscopic models for dendritic growth

Clustering

Clústeres, Plataformas y Asociaciones Internacionales Advanced Materials Initiative 2030 (AMI2030) Batteries European Partnership Association

Three-dimensional needle network model for dendritic growth with fluid flow

Defensa de Tesis Doctoral de Jing Zhang titulado «Metal-Organic Frameworks (MOFs) Derived Hierarchical Hybrids as Fire Retardants for Epoxy Composites» – 22 de enero, 2021.

La Defensa Doctoral tendrá lugar el 22 de enero a las 12:00 hr. La asistencia será a modo remoto. La disertación se titula "Metal-Organic Frameworks (MOFs) Derived Hierarchical Hybrids as Fire Retardants for Epoxy Composites".

A Machine Learning Model to Detect Flow Disturbances during Manufacturing of Composites by Liquid Moulding

Multiscale Characterization of the Mechanical Properties of Fibrin and Polyethylene Glycol (PEG) Hydrogels for Tissue Engineering Applications

Understanding interlaminar toughening of unidirectional CFRP laminates with carbon nanotube veils

Ferromagnetic epitaxial Cr2O3 thin films grown on oxide substrates by Pulsed Laser Deposition

Origin of the electrocatalytic activity in carbon nanotube fiber counter-electrodes for solar-energy conversion

Defensa de Tesis Doctoral de Jaime Castro titulado «X-Ray Tomographic Investigation of Resin Flow in Liquid Moulding of Composite Materials» – 15 de enero, 2021.

La Defensa Doctoral tendrá lugar el 15 de enero a las 10:00 hr. La asistencia será a modo remoto. La disertación se titula "X-Ray Tomographic Investigation of Resin Flow in Liquid Moulding of Composite Materials".

Tip dynamics for equiaxed Al-Cu dendrites in thin samples : Phase-field study of thermodynamic effects

Hierarchical layered double hydroxide nanosheets/phosphorus-containing organosilane functionalized hollow glass microsphere towards high performance epoxy composite: Enhanced interfacial adhesion and bottom-up charring behavior

An Overview of the Flame Retardants for Poly(vinyl chloride): Recent States and Perspective(dagger)

DELIGHTED holds first progress meeting

The DELIGHTED project partners held their first online progress meeting on January 25, 2021. The outcomes of research activities were presented and discussed. The research plans for the next 6 months were updated.

Toward crystalline porosity estimators for porous molecules

Investigation of Solidification and Precipitation Behavior of Si-Modified 7075 Aluminum Alloy Fabricated by Laser-Based Powder Bed Fusion

High temperature strength retention of Cu/Nb nanolaminates through dynamic strain ageing

Chemical Regeneration of Thermally Conditioned Basalt Fibres

Influencing parameters on measurement accuracy in dynamic mechanical analysis of thermoplastic polymers and their composites

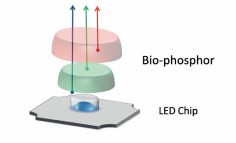

Quo Vadis Biogenic Phosphors?

La revista LED professional publica un artículo sobre los objetivos del proyecto ARTIBLED en su edición de Diciembre (página 64). LED professional publicará también los principales resultados que se obtengan a lo largo del proyecto .

A Methodology for the Statistical Calibration of Complex Constitutive Material Models: Application to Temperature-Dependent Elasto-Visco-Plastic Materials

Development of New 14 Cr ODS Steels by Using New Oxides Formers and B as an Inhibitor of the Grain Growth

Javier Llorca habla en RNE sobre andamios de magnesio en 3D para tratar grandes fracturas óseas

Javier Llorca, líder del grupo de Mecánica de Materiales, habla en el programa «Marca España» de RNE sobre andamios de magnesio fabricados mediante impresión 3D para el tratamiento de grandes fracturas óseas. Puedes escuchar la entrevista aquí (a partir del minuto 3:50)

Tough sheets of nanowires produced floating in the gas phase

Bio-based rigid polyurethane foam from castor oil with excellent flame retardancy and high insulation capacity via cooperation with carbon-based materials

A Study of the Microstructure, Texture and Tensile Properties of 1060/Al-TiC/1060 Sandwich Composites Prepared by Hot-Roll Bonding

A comparison of field assisted hot pressing and hot isostatic pressing for gas atomized Ti-22Al-26Nb(at.%) and Ti-22Al-26Nb-5B(at.%) powders

Basalt Fiber Modified Ethylene Vinyl Acetate/Magnesium Hydroxide Composites with Balanced Flame Retardancy and Improved Mechanical Properties

High temperature mechanical properties and microstructure of hard TaSiN coatings

First Year Assessment de Maral Sarebanzadeh titulado «Role of the grain boundary on the deformation of magnesium» – 22 de Diciembre, 2020.

Resumen: Understanding and describing plastic deformation in polycrystalline materials is fundamentally challenging due to the complex atomic rearrangements that must occur at grain boundaries. Thus, there is a significant need to develop new techniques to study, correlate, and describe

Nuestra alumni Jingya Wang obtiene el premio Universitario a la mejor tesis doctoral

La tesis doctoral de Jingya Wang, titulada “Investigación de alto rendimiento de la difusión y endurecimiento en solución sólida de aleaciones de HCP Mg”, ha obtenido el Premio de la Universidad Politécnica de Madrid a la mejor tesis doctoral. La tesis fue asesorada por el Prof. J. LLorca y el Prof.

Grandes científicas en la “Gran Pantalla” en la Noche Europea de los Investigadores e Investigadoras de Madrid 2020

El pasado viernes 27 de noviembre, la Residencia de Estudiantes de Madrid volvió a acoger la actividad que los Institutos IMDEA organizamos dentro de la Noche Europea de los Investigadores e Investigadoras de Madrid, coordinado por la Fundación para el Conocimiento madrimasd. La actividad de

High-fidelity computational micromechanics of first-fibre failure in unidirectional composites: Deformation mechanisms and stress concentration factors

Nanomechanical characterization of the fracture toughness of Al/SiC nanolaminates

ITP Aero e IMDEA Materiales desarrollan un programa de I+D para simular la fabricación en 3D pionero en el mundo

ITP Aero e IMDEA Materiales colaboran en un programa de I+D, llamado ENVIDIA, que tiene como objetivo desarrollar software capaz de simular la producción de componentes aeronáuticos usando tecnologías de fabricación aditiva (también conocido como impresoras 3D). Las actividades de este programa

(MAT4.0) FABRICACIÓN INTELIGENTE DE MATERIALES AVANZADOS PARA EL TRANSPORTE, LA ENERGÍA Y LA SALUD

Funding: Regional Government of Madrid, Technology 2018 callRegion: MadridProject period: 2019 – 2022Principal Investigators: Jon Mikel Molina Aldareguia (jon.molina@imdea.org) MAT4.0-CM is a research program in intelligent manufacturing of advanced materials for energy, transport and health, with

High strain rate compression of epoxy micropillars

Polydopamine-assisted strategies for preparation of fire-safe polymeric materials: A review

(TOPOMAG-3D) RELACIÓN MICROESTUCTURA-TOPOLOGÍA-PROPIEDADES MECÁNICAS DE ANDAMIOS BASADOS EN MG FABRICADOS POR IMPRESIÓN 3D PARA APLICACIONES BIOMÉDICAS

Proyectos I+D+i -Modalidades «Retos Investigación» y «Generación de Conocimiento»Proyecto PID2019-109962RB-I00 financiado por MCIN/AEI /10.13039/501100011033Region: NationalProject period: 2020 – 2023Principal Investigator: Federico Sket (federico.sket@imdea.org)Magnesium and its alloys, as

Revealing the Mechanism of Electrochemical Lithiation of Carbon Nanotube Fibers

National Geographic se hace eco de la investigación de IMDEA Materiales sobre estructuras biodegradables impresas en 3D para regeneración ósea

Un equipo de ingenieros españoles ha conseguido crear un andamio basado en magnesio que permite recomponer grandes fragmentos óseos. El nuevo dispositivo, en fase de estudio, no es tóxico, es biodegradable y no genera rechazo. Además, permite la regeneración del tejido sin complicaciones por lo que

La noche Europea de los investigadores en Madrid

Investigadores de los 7 institutos IMDEA hablarán de grandes investigadoras que han sido o podrían ser protagonistas en la gran pantalla. Nuestras compañeras Monica Echeverry Rendon y Eugenia Nieto Valeiras serán las protagonistas de este gran encuentro. Tendrá lugar el 27 de noviembre de

Dr. Pietro Antonio Martelli

First Year Assessment de Xiaolu Li, titulado «Highly-sensitive Flame-retardant Smart Sensor for Early Warning Fire Detection to Polymer-based Materials» – 23 de noviembre a las 14:30 hr

Resumen: Fire hazard is one of the major disasters that threaten public safety seriously. Once a fire occurs, the fire will spread quickly along some flammable materials, which bring much difficulty to control the fire. The fire hazard will cause casualties, considerable property loss and medical

Defensa de Tesis Doctoral de Yunfu Ou titulado «Hybrid FRP/CNT veil hierarchical composites with enhanced interlaminar properties and integrated multifunctionalities» – 20 de noviembre, 2020

La Defensa Doctoral tendrá lugar el 20 de noviembre a las 12:00 hr. La asistencia será a modo remoto. La disertación se titula "High Strain Rate Mechanical Behavior of Advanced High Strength Steels" Abstract: While FRP composites are extensively used in structural components due to their

First-principles analysis of precipitation in Mg-Zn alloys

Quantitative multi-scale characterization of single basalt fibres: Insights into strength loss mechanisms after thermal conditioning

Microstructure evolution and adiabatic heating during dynamic biaxial deformation of a 304 stainless steel

Epoxy thermosets and materials derived from bio-based monomeric phenols: Transformations and performances

Materials Horizons Emerging Investigator Series: Juan José Vilatela, IMDEA Materials Institute, Spain

Diez investigaciones «made in Madrid» en la vanguardia de la investigación internacional

La Comunidad de Madrid es la región que más dinero invierte en Investigación y Desarrollo. El gasto en 2018 superó los 3.900 millones de euros en un sector que emplea a más de 50.000 personas. En términos porcentuales, es el 1,71% del PIB autonómico, sólo superado en este aspecto por el 1,91% de

La Comunidad de Madrid desarrolla 3.100 proyectos de I+D al año, que generan 375 millones de €

La Comunidad de Madrid desarrolla anualmente 3.100 proyectos de investigación y desarrollo, lo que la convierte en un referente internacional en investigación gracias a la labor de sus catorce universidades, los ocho institutos de investigación sanitaria acreditados, así como por los siete

S-XCT experimental determination of local contact angle and meniscus shape in liquid moulding of composites

Lignin Doped Carbon Nanotube Yarns for Improved Thermoelectric Efficiency

Effects of Ce doping on mechanical properties of M7C3 carbides in hypereutectic Fe-Cr-C hardfacing alloy

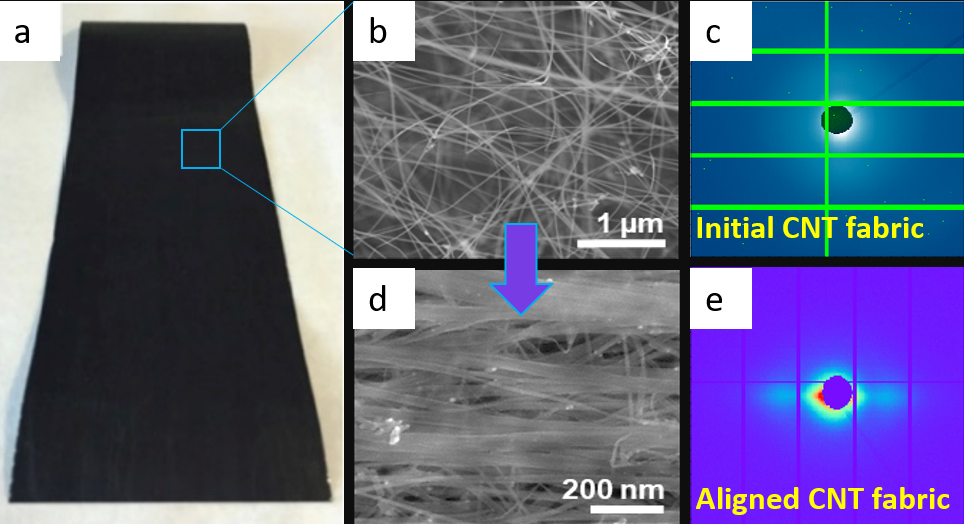

Los resultados del proyecto MSCA IF ENERYARN sobre tejidos multifuncionales de CNTs han sido destacados por la Comisión Europea

En el proyecto MSCA IF ENERYARN , Dr. Anastasiia Mikhalchan trabajó en el desarrollo de estrategias para estirar hilos de nanotubos de carbono (CNTs) y en nuevas formas de estudiar materiales compuestos capaces de almacenar energía. Los nuevos métodos trataron el problema del alineamiento de las

(SiNERGY) Silicon nanowire fabrics for high energy density batteries

Project details Funding: ERC Proof of Concept, Horizon 2020 Programme (Grant Agreement 963912) Partners: IMDEA Materials Institute Project period: 01/10/2020 – 31/03/2022 Researcher Dr. Juan José Vilatela Abstract Meeting European energy storage in transport, stationary and emerging

The influence of underlying microstructure on surface stress and strain fields calculated by crystal plasticity finite element method

Coordinating mechanical performance and fire safety of epoxy resin via functionalized nanodiamond

Polymer-based ceramifiable composites for flame retardant applications: A review

Teresa Pérez-Prado habla en RNE sobre el potencial de la impresión 3D

Teresa Pérez-Prado, líder del grupo de Metalurgia Física, habla en el programa "Gente Despierta" de RNE sobre los problemas que puede resolver la impresión 3D. Puedes escuchar la entrevista aquí (a partir del minuto 5:30)

Surface engineering of magnesium hydroxide via bioinspired iron-loaded polydopamine as green and efficient strategy to epoxy composites with improved flame retardancy and reduced smoke release

Multiscale SAXS/WAXD characterisation of the deformation mechanisms of electrospun PCL scaffolds

Alumni Newsletter Nº 5

Click in the image to access the full newsletter

Hierarchically tailored hybrids via interfacial-engineering of self-assembled UiO-66 and prussian blue analogue: Novel strategy to impart epoxy high-efficient fire retardancy and smoke suppression

Polycarbonate/Sulfonamide Composites with Ultralow Contents of Halogen-Free Flame Retardant and Desirable Compatibility

New instrumentation and analysis methodology for nano-impact testing

MSCA Fellow Series: Enhancing mutual alignment and stress-transfer in multiyarn CNT fabrics

"We developed a method to enhance mutual alignment and stress-transfer in multiyarn CNT fabrics, which is a critical step for scaling up the CNT fabrics manufacturing process and further industrial implementation." Dr. Anastasiia Mikhalchan graduated from the Saint-Petersburg State University of

Anastasiia Mikhalchan

"We developed a method to enhance mutual alignment and stress-transfer in multiyarn CNT fabrics, which is a critical step for scaling up the CNT fabrics manufacturing process and further industrial implementation." Dr. Anastasiia Mikhalchan graduated from the Saint-Petersburg State University of

Recent Progress on Metal-Organic Framework and Its Derivatives as Novel Fire Retardants to Polymeric Materials

Semana de la ciencia y la Innovación de Madrid en IMDEA Materiales

Un año más, IMDEA Materiales estará presente en la Semana de la Ciencia y la Innovación de Madrid, que se celebrará del 2 al 15 de noviembre de 2020. Este año las actividades serán de forma «online» con la siguiente temática: “Retos de la impresión 3D de materiales compuestos de alta resistencia”

Scalable graphene-based nanocomposite coatings for flexible and washable conductive textiles

Newsletter suscription

Let's connect Keep up with IMDEA Materials updates NEWSLETTER Data controllerFUNDACIÓN IMDEA MATERIALES with legal address at C/Eric Kandel, 2 – Tecnogetafe – 28906 Getafe (Madrid). Purpose: To manage your subscription to our newsletter and send it periodically. Your rights:

Juan José Vilatela habla en RNE acerca de los electrodos basados en silicio desarrollados en su grupo

Juan José Vilatela, líder del grupo de Nanocompuestos Multifuncionales y reciente beneficiario de una Beca Proof of Concept del European Research Council, habla en el programa “Marca España” de RNE, sobre el potencial de los electrodos de silicio desarrollados en su grupo para aplicaciones de

LEDs de producción bacteriana

Este artículo de Wiley Analytical Science explica la estrategia de investigación con la que se lleva a cabo el proyecto ARTIBLED.

Recent Advances in Solid‐State Lighting Devices Using Transition Metal Complexes Exhibiting Thermally Activated Delayed Fluorescent Emission Mechanism

Synergistic effect of expandable graphite and phenylphosphonic-aniline salt on flame retardancy of rigid polyurethane foam

Scientific highlights

Towards Mimicking the Fetal Liver Niche: The Influence of Elasticity and Oxygen Tension on Hematopoietic Stem/Progenitor Cells Cultured in 3D Fibrin Hydrogels

Un grupo de investigación de IMDEA Materiales ha desarrollado un silicio flexible que revolucionará los vehículos eléctricos

Las baterías producidas con este nuevo material permitirán aligerar los vehículos, aumentar la distancia que recorren y reducir el tiempo de carga. Un grupo de investigadores del instituto madrileño IMDEA Materiales dirigido por Juan José Vilatela ha logrado desarrollar silicio flexible en

IMDEA Materiales participa en el documento «Prioridades Industriales de I+D+I en Fabricación Avanzada»

El documento ha sido elaborado por la Plataforma Tecnológica Aeroespacial Española (PAE), con el apoyo de un grupo de trabajo liderado por Aernnova y formado por ACITURRI, AIMPLAS, AIRBUS, AIRGRUP, AIMEN, CEIT, COMET Ingeniería, EHU / CFAA, FIDAMC, HEROUX -DEVTEK, ITP AERO, OBUU Tech y

Arranca el proyecto ENTENTE

El proyecto ENTENTE (Base de datos europea para la modelización multiescala de los daños por radiación) ha comenzado el 1 de septiembre de 2020 y durará 48 meses. El objetivo de este proyecto es diseñar una nueva base de datos europea de materiales experimentales/modelos para recoger y almacenar

(TESCOM) TAILORED LIGHTWEIGHT SANDWICH COMPOSITES WITH MULTIFUNCTIONAL PROPERTIES AND GOOD DESIGNABILITY

Funding: European Union, Marie Skłodowska-Curie Individual Fellowships, Horizon 2020 Programme (Grant Agreement 895931)

(ENTENTE) EUROPEAN DATABASE FOR MULTISCALE MODELLING OF RADIATION DAMAGE

Funding: H2020. European Atomic Energy Community (EURATOM) Region: European Project period: 2020 – 2024 Partners: Centro de Investigaciones energéticas, medioambientales y tecnológicas-CIEMAT (Project Coordinator), Fundación IMDEA Materiales, Bay Zoltan Alkalmazott Kutatasi Kozhasznu nonprofit

Transparent and flexible high-power supercapacitors based on carbon nanotube fibre aerogels

Dynamic Tensile Testing of Needle-Punched Nonwoven Fabrics

Powder metallurgy and high-entropy alloys: update on new opportunities