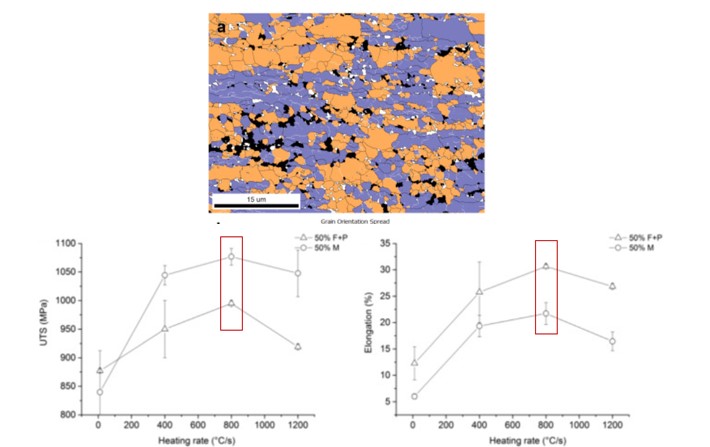

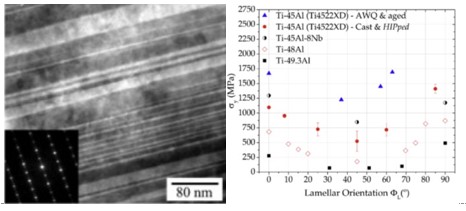

IMDEA Materials has developed technologies for ultrafast processing of advanced metallic materials in a thermo-mechanical simulator (GLEEBLE 3800). They allow to precisely control the thermo-mechanical processing at high heating/cooling rates, as well as at high strain rate plastic deformation. Ultrafast processing of metallic materials undergoing phase transformations during heating/cooling allows to generate unique multi-phase refined microstructures, which often cannot be achieved via standard thermal or thermo-mechanical processing. Such microstructures often demonstrate outstanding mechanical performance (for example, improved mechanical strength combined with high tensile ductility and improved high cycle fatigue resistance). The examples of successfully ultrafast processed materials at IMDEA Materials, which show improved performance, include a wide range of carbon steels [1, 2] and titanium aluminides [3] (see Fig. 1).

Fig. 1. a) Refined multiphase microstructure in a Fe-0.19C-1.6Mn-1Al-0.5Si steel via ultrafast heating at 800 oC/s and the related effect of heating rate on strength and ductility; b) nanolamellar structure generated in a Ti4522XD alloy via ultrarapid processing (AWQ-aged) and its improved strength (blue dots) compared to other alloy’s conditions.

Fig. 1. a) Refined multiphase microstructure in a Fe-0.19C-1.6Mn-1Al-0.5Si steel via ultrafast heating at 800 oC/s and the related effect of heating rate on strength and ductility; b) nanolamellar structure generated in a Ti4522XD alloy via ultrarapid processing (AWQ-aged) and its improved strength (blue dots) compared to other alloy’s conditions.IMDEA Materials expertise also includes the capabilities to perform a thorough multiscale microstructural characterization of these alloys and their mechanical characterization on macro-, micro-, and nano-scales. This allows to study the link between ultrafast processing parameters, microstructure of individual micro-constituents and their properties, and to relate it to the performance of the bulk material. Thus gained fundamental understanding of processing-microstructure-properties relationship enables further optimization of the complex multi-phase microstructure to reach outstanding properties.

For more information about this technology, reach us at proyectos.materiales@imdea.org

[1] The effect of soaking time after ultrafast heating on the microstructure and mechanical behavior of a low carbon steel.

M.A. Valdes-Tabernero, R.H. Petrov, M.A. Monclus, J.M. Molina-Aldareguia

Materials Science and Engineering A, 765, 138276, 2019.

DOI: https://doi.org/10.1016/j.msea.2019.138276

[2] The sensitivity of the microstructure and properties to the peak temperature in an ultrafast heat treated low carbon-steel.

M.A. Valdes-Tabernero, A. Kumar, R.H. Petrov, M.A. Monclus, J.M. Molina-Aldareguia, I. Sabirov

Materials Science and Engineering A, 776, 138999, 2020.

DOI: https://doi.org/10.1016/j.msea.2020.138999

[3] Effect of nanoscale thick lamellae on the micromechanical response of a TiAl alloy.

A.J. Palomares-García, I. Sabirov, M.T. Pérez-Prado, J.M. Molina-Aldareguia

Scripta Materialia, 139, 17-21, 2017.

DOI: https://doi.org/10.1016/j.scriptamat.2017.06.002