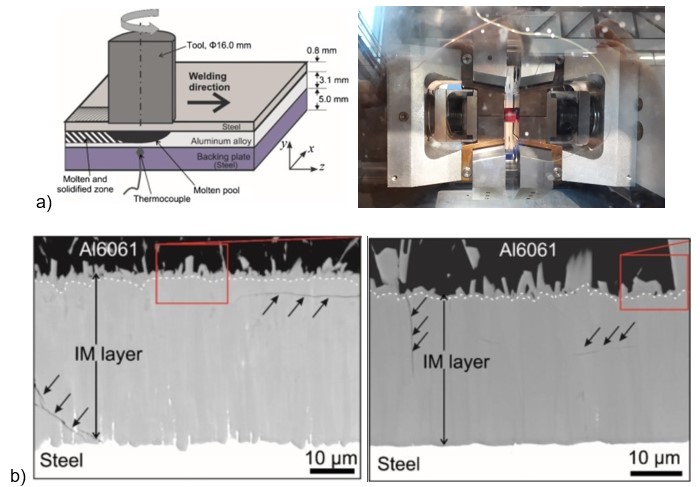

IMDEA Materials has developed a physical simulation tool to predict joinability of dissimilar metallic materials with different melting points. Very small samples of the actual dissimilar materials are subjected to the same thermal and mechanical profiles in a thermo-mechanical simulator (GLEEBLE 3800) that they would experience on a larger scale. Analysis of the processed samples allows to determine the quality of the joint, the microstructure and properties of the newly formed interface, as well as to pick up the most optimum processing parameters for joining. This approach allows making faster ‘go / no go’ decisions for joining dissimilar materials, and dramatically reduces the time and cost to develop novel processing routes. This technology has already successfully used for physical simulation of friction melt bonding of a steel and Al alloy (see Fig. 1 and [1]) and can be further optimized for physical simulation of metal/polymer or metal/composite joining.

IMDEA Materials has also significant expertise in the multiscale microstructural characterization of joints and interfaces, as well as their mechanical characterization on various scales. This allows to study the link between joining parameters, microstructure of joints and their properties. The understanding of the processing – microstructure – properties relationship enables further optimization of joining processes.

For more information, reach us at proyectos.materiales@imdea.org

[1] A new physical simulation tool to predict the interface of dissimilar aluminum to steel welds performed by friction melt bonding.

T. Sapanathan, N. Jimenez-Mena, I. Sabirov, M.A. Monclús, J.M. Molina-Aldareguía, P. Xia, L. Zhao, A. Simar

Journal of Materials Science & Technology, 35, 2048-2057, 2019.

DOI: https://doi.org/10.1016/j.jmst.2019.05.004