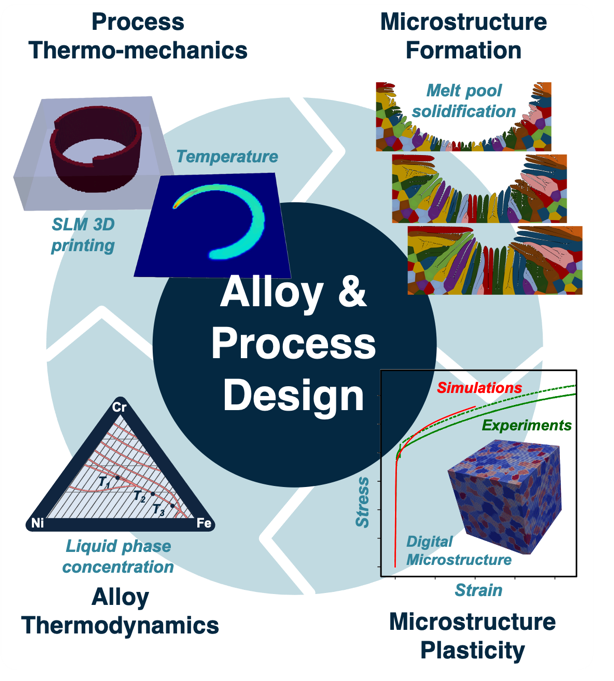

As part of its strategic initiative on damage-tolerant additive manufacturing, IMDEA Materials develops a suite of physics-based computational models and simulation tools aimed at linking processing, microstructures and properties, in order to accelerate the discovery and deployment of new alloys designed specifically for Additive Manufacturing (AM) with outstanding properties and to optimize processing conditions for AM of metals and alloys (see Fig. 1). State-of-the-art models developed and combined within this research thrust include:

• Finite Element (FE) simulation of macroscopic processing (e.g. Selective Laser Melting (SLM)) in order to predict residual stresses, printed part distortion, and local thermal history used as input toward lower-scale models.

• Phase-Field (PF) modeling of microstructure formation in the melt pool in fusion-based processes (e.g. SLM) to predict grain texture and solute segregation.

• Crystal Plasticity (CP) modeling and computational homogenization to predict the mechanical response and performance (e.g. fatigue life) of complex heterogeneous microstructures.

• Computational Thermodynamics (CalPhaD) to calculate temperature-dependent thermo-physical properties, stable phases, and transformation temperatures, of complex multicomponent alloys.

• Advanced characterization methods (e.g. powder characterization, microstructure characterization, fatigue, testing, high-temperature micro/nano-mechanics, …) is used to validate and/or calibrate models to ensure their predictive capabilities.

Ongoing activities include combining computational thermodynamics, FE process thermomechanics, PF modeling of microstructure formation, and CP for SLM of Nickel-based superalloys for high-temperature aeronautical applications; and leveraging computational thermodynamics and advanced material characterization to design compositionally/functionally graded steels and metal components via Direct Energy Deposition (DED) technology.