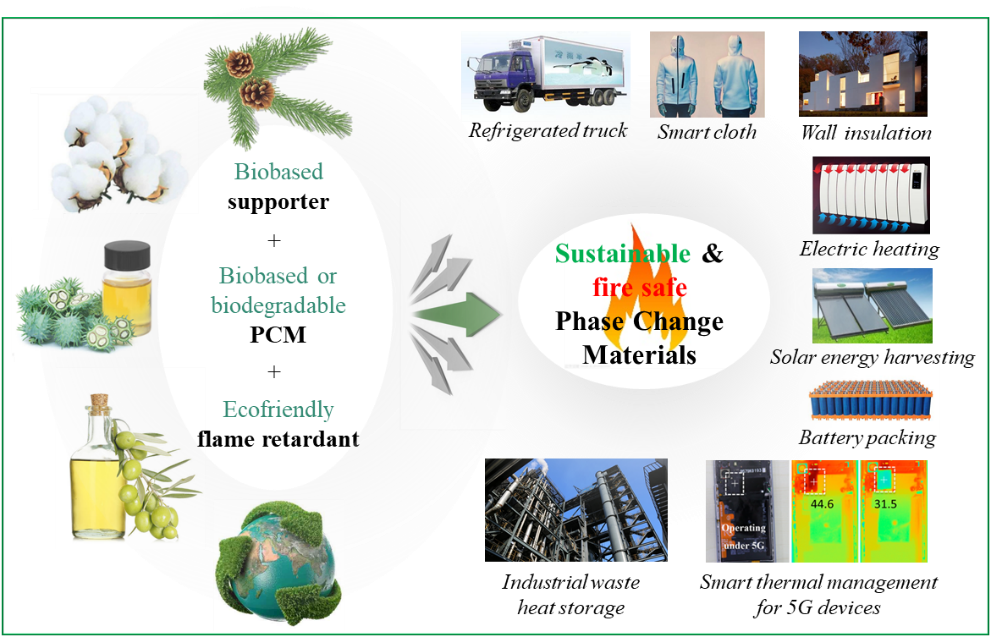

IMDEA Materials can design and prepare novel Phase Change Materials (PCMs) for thermal energy storage applications that: are prepared in an easy and green pathway and, at the same time, have high mechanical performance, fire safety, form stability, phase transition enthalpy, and thermal conductivity. So far, the main focus of IMDEA Materials has been on the following systems, but the existing know-how can be applied to other systems:

- Bio-based PGS-encapsulated PEG as sustainable and fire-safe PCMs:

Bio-based polymer matrixes (Poly (Glycerol Succinic acid), PGS) were chosen or synthesized as sustainable supporter for the PolyEthylene Glycol (PEG) with different molecular weight, giving rise to form-stable PCMs. Different kinds of flame retardants (e.g. Ammonium Polyphosphate (APP), expandable graphite) were further used for the fire safety modification. This PCMs can be applied to wall insulation and temperature control for electric heating, refrigerated vehicles, etc (see Fig. 1). Currently, IMDEA Materials can produce the PCMs in kilogram-scale. It is expected to enlarge the production scale in the future easily, because the preparation process is quite convenient and efficient.

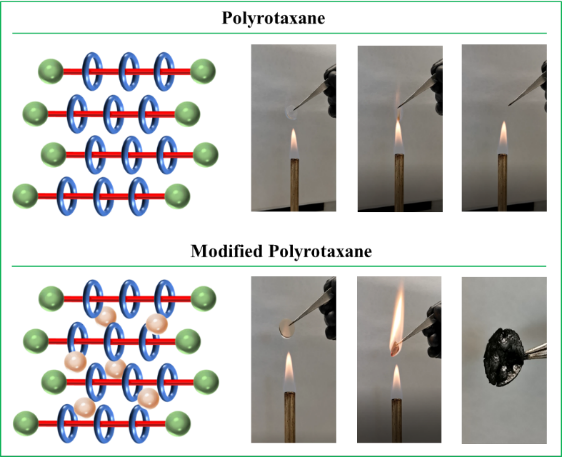

- Polyrotaxane (PRX) based fire-safe PCMs:

Here, PRX composites were prepared by casting the PRX solutions mixing with some other functional additives. Most suitable PRXs were explored and screened and key parameters were optimized (toughness and strength, cost, shape stability, latent heat of phase transformation and thermal conductivity). Moreover, different flame retardant modification methods (both physical and chemical) were tested to improve the fire safety of PCMs (see Fig. 2). This PCMs can be widely applied into electric devices temperature control (battery packs) and smart textiles.