Infrastructure

IMDEA Materials Institute has well-equipped laboratories with the-state-of-the-art facilities for organic and inorganic synthesis, polymer processing, fire testing, and mechanical and thermal analysis, which provide a necessary and strong support to carry out the study on advanced polymer materials, composites and nanocomposites. In addition, some other related instruments such as atomic force microscope (Park XE150), scanning electron microscope (EVO MA15, Zeiss), X-ray computer-assisted 3D nanotomograph (Nanotom, Phoenix), and nano-indentation system are also available on the measurement platform of IMDEA Materials institute. Advanced X-ray diffraction (XRD) and transmission electron microscope (TEM) will be available in IMDEA Materials Institute in 2015.

Vacuum Induction Melting and Casting System with Directional Solidification Device (VSG 002 DS, PVA TePla)

System employed for melting of a wide range of metals, alloys or special materials under high vacuum, fine vacuum or different gas atmospheres with subsequent casting into moulds or forms. In addition, it is equipped with a directional solidification device, which enables growth of single crystals and aligned columnar structures.

Arc melting and casting furnace (Arc 200, Arcast Inc.)

For melting, alloying, casting, rapid solidification for high melting point elements and alloys up to 3500°C using a clean ceramic free cold crucible process. The furnace offers many options including: tilt casting, centrifugal casting, suction casting, zone melting under inert atmosphere or high vacuum.

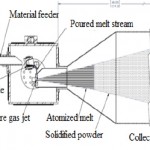

Gas atomizer (Arc 200, Arcast Inc.)

For a gas atomization under inert atmosphere or high vacuum. During the gas atomization process, the molten material is atomized thanks to inert gas jets into fine metal droplets which cool down during their fall in the atomizing tower. Metal powders obtained by gas-atomization offer a perfectly spherical shape combined with a high cleanliness level.